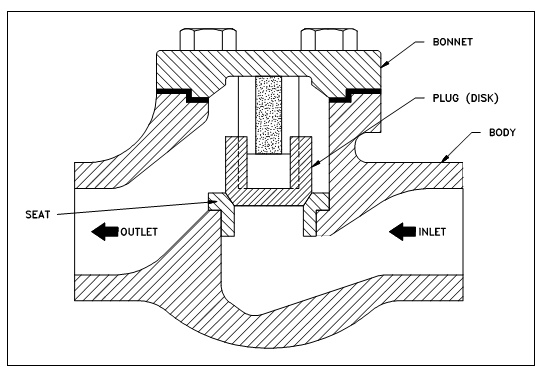

Lift Check Valves:

A lift check valve, described in Figure, is generally used in piping systems in that globe valves are being used since a flow control valve. They have same seating arrangements as globe valves.

Lift check valves are appropriate for installation in horizontal or vertical lines along with upward flow. They are recommended for use along with steam, air, water, gas, and on vapor lines within high flow velocities. Those valves are available within three body patterns: angle, horizontal, and vertical.

Figure: Lift Check Valve

Flow to lift check valves have to be always entering below the seat. Since the flow enters then the disk or ball is raised inside guides from the seat through the pressure of the upward flow. While the flow reverses or stops, the disk or ball is forced onto the seat of the valve through both the gravity and backflow.

A few kinds of lift check valves might be installed horizontally. In that design, the ball is suspended through a system of guide ribs. This category of check valve design is commonly employed within plastic check valves.

The seats of metallic body lift check valves are either integral along with the body or hold renewable seat rings. Disk construction is same to the disk construction of globe valves along with either composition disks or metal. Metal disk and seat valves could be reground using the similar methods as is used for globe valves.