Butterfly Check Valves:

Butterfly check valves have a seating arrangement same to the seating arrangement of butterfly valves. The Flow features by these check valves are same to the flow features of butterfly valves. In other words, butterfly check valves are quite often used in systems using butterfly valves.

Further, the construction of the butterfly check valve body is such in which ample space is given for unobstructed movement of the butterfly valve disk inside the check valve body without the essential of installing spacers.

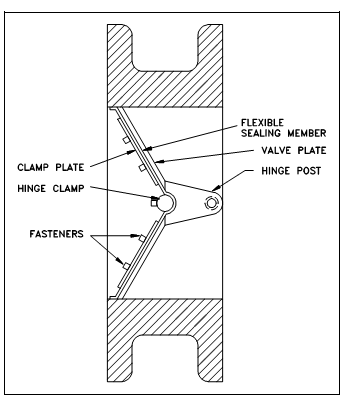

Figure: Butterfly Check Valve

The butterfly check valve is designed based on a flexible sealing member against the bore of the valve body at an angle of 45o. The short distance the disk have to be move from full open to full close inhibits the "slamming" action found in a few other categories of check valves. Above figure described the internal assembly of the butterfly check valve because the flow features are same to the flow features of butterfly valves, the applications of these valves are much the similar. In addition, since of their associatively quiet operation they search application in ventilation, heating, and air conditioning systems. Simplicity of design also allows their construction in large diameters - up to 72 inches.

As along with butterfly valves then the basic body design lends itself to the installation of seat liners constructed of several materials. This allows the construction of a corrosion-resistant valve at less expense than would be encountered if it were essential to construct the whole body of the higher alloy or more expensive metal. That is particularly true in constructions like as those of titanium.

Flexible sealing members are available within Buna-N, Nordel, Neoprene, Hypalon, Viton, Tyon, Butyl, Urethane, Silicone, and TFE as standard, along with other materials available in special sequence.

The valve body necessary is a length of pipe which is fitted along with flanges or has grooved, threaded, or plain ends. An interior is bored to a fine finish. The flanged end units could have liners of several metals or plastics installed depending upon the service needs. Fasteners and Internals are always of the similar material as the liner.

Butterfly check valves might be installed horizontally or vertically along with the vertical flow either downward or upward. Care should be taken to ensure in which the valve is installed so which the entering flow comes from the hinge post end of the valve; or else, all flow will be stopped.