Refractory Materials

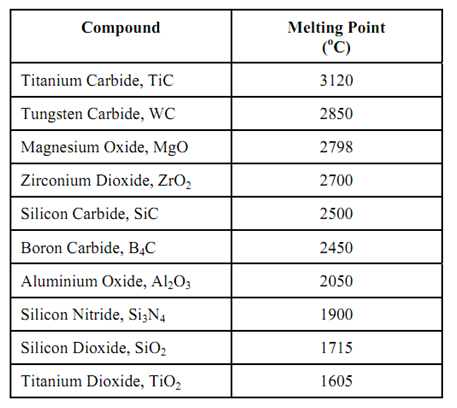

Refractory materials are made up of engineering ceramics, which are quite expensive in their pure forms. These materials are also hard to form. Most of industrial refractory materials are built of mixture of ceramic compounds. These compounds are heat resistant due to their high melting point. Table explains melting point temperatures of a few ceramic compounds.

Table : Melting Points of Some Ceramic Compounds

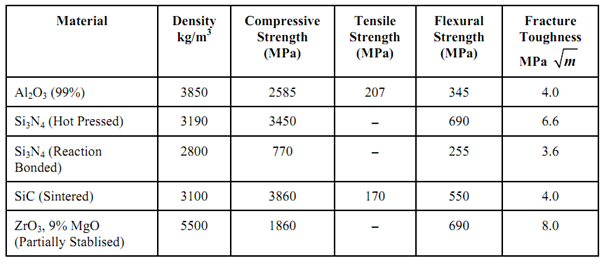

The compounds that are most extensively used in industrial refractory materials are Al2O3, Si3N4, SiC and ZrO2. Some other refractory oxides are mixed up with these compounds. Some thermal properties of these ceramics were explained earlier. It has already been stated that these are brittle materials and illustrated low tensile strength. They are more recognized by their compressive strength & flexural strength. Their fracture toughness is also low .Table describes mechanical properties of extensively utilized ceramic materials. It is seen from these data that compressive strength is more than 10 times higher than tensile strength. However, one must keep in mind that brittle material, like as ceramics are, may not yield consistent values of strength particularly tensile strength because of presence of several micro defects. Statistical approach should be adopted if load carrying member in ceramic has to be designed. At the mean time it might also be understood that larger components with larger surface area have higher probability of carrying crack as defects and hence large sizes should be avoided. The experimental methods for tensile strength determination do not prove efficient and for this cause 3 point bend tests give better strength indicator (that means flexural strength). The modulus of elasticity of these materials is quite high-often as high as 1000 to 2000 times tensile strength. The modulus of elasticity is mainly based upon the level of porosity & proportion of impurities. A significant high temperature behaviour linked with ceramics is that while it may not sustain certain load at low temperature, the same load might be sustained beyond certain high temperature. This phenomenon occurs due to tip rounding of crack like flaw at high temperature. This rounding of flaw brings down the stress concentration factor to a finite value from infinity. The temperatures beyond which ceramics might be useful to carry stresses are determined in respect of several ceramics. For instance, for alumina this temperature is 1400oC while for silicon nitride it is 1600oC.

Table: Mechanical Properties of a Few Ceramics Materials

In the following sections we explain a few refractory materials which are widely utilized along with indication of manufacturing utilized to bring them in usable forms.