Operating Characteristics of a Centrifugal Pump

Generally, a centrifugal pump generates a relatively low pressure rise in the fluid. Such pressure rise can be anywhere from numerous dozen to numerous hundred psid across a centrifugal pump by a single stage impeller. The word PSID (i.e., Pounds Force per Square Inch Differential) is equal to ?P. In this situation, it is the pressure difference among the suction and discharge of a pump. PSID can also be employed to explain a pressure drop across a system component (i.e., filters, strainers, heat exchangers, valves, demineralizers, and so on.). Whenever a centrifugal pump is operating at a constant speed, a rise in the system back pressure on the flowing stream causes a decrease in the magnitude of volumetric flow rate which the centrifugal pump can sustain.

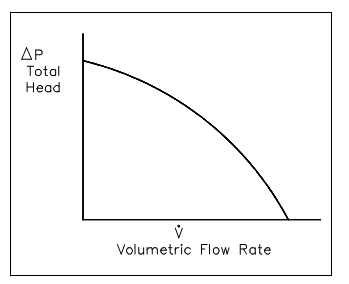

Analysis of the association among the volumetric flow rate (V) which a centrifugal pump can sustain and the pressure differential across the pump (?Ppump) is based on different physical characteristics of the pump and the system fluid. The variables computed by design engineers to establish this association involve the pump efficiency, the rotational speed, the power supplied to the pump, the diameter of the impeller and blading, the fluid density, and the fluid viscosity. The outcome of this complex analysis for a usual centrifugal pump operating at one specific speed is illustrated by the graph shown below.

The pump head, on the vertical axis, is the difference among system back pressure and the inlet pressure of the pump (?Ppump). The volumetric flow rate (V), on the horizontal axis, is the rate at which fluid is flowing via the pump. The graph supposes one specific speed (N) for the pump impeller.