Wearing Rings:

Centrifugal pumps holds rotating impellers inside stationary pump casings. To permit the impeller to rotate freely inside the pump casing, a small clearance is designed to be managed among the impeller and the pump casing. For maximize the effectiveness of a centrifugal pump, it is essential to minimize the amount of liquid leaking by this clearance from the high pressure or discharge side of the pump back to the low pressure or suction side.

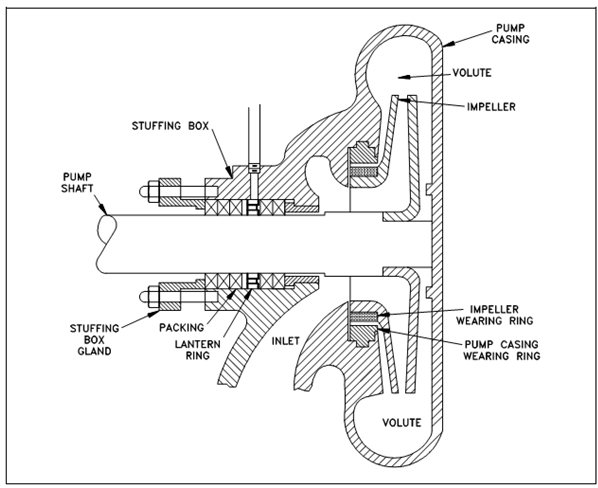

Figure: Centrifugal Pump Components

A few wear or erosion will occur at the point whereas the impeller and the pump casing nearly come into contact. This wear is because of the erosion caused through liquid leaking by this tight clearance and another causes. As wear occurs then the clearances become larger and the rate of leakage increases. Finally, the leakage could become unacceptably large and maintenance would be needed on the pump.

To reduce the cost of pump maintenance, several centrifugal pumps are designed along with wearing rings. A Wearing rings are replaceable rings which are attached to the impeller and/or the pump casing to permit a small running clearance among the impeller and the pump casing without causing wear of the actual impeller or pump casing material. Those wearing rings are designed to be exchanged periodically in during the life of a pump and avoid the more costly replacement of the impeller or the casing.