Multi-Stage Centrifugal Pumps:

A centrifugal pump along with a single impeller which could develop a differential pressure of more than 150 psid among the suction and the discharge is hard and costly to construct and design.

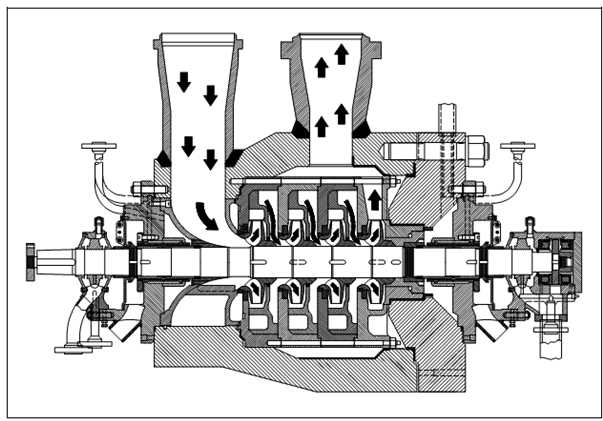

A more economical approach to developing high pressures along with a single centrifugal pump is to involve multiple impellers on a general shaft inside the similar pump casing. Internal channels in the pump casing route the discharge of one impeller to the suction of other impeller.

Figure displays a diagram of the arrangement of the impellers of a four-stage pump. A water enters the pump from the top left and passes by every of the four impellers in series and going from left to right. Water goes from the volute surrounding the discharge of one impeller to the suction of the next impeller.

A pump stage is described as in which portion of a centrifugal pump consisting of one impeller and its related parts. Many centrifugal pumps are single-stage pumps, holding just one impeller. A pump holding seven impellers inside a single casing would be referred to as a seven-stage pump or, or commonly, as a multi-stage pump.

Figure: Multi-Stage Centrifugal Pump