True Centrifugal Casting:

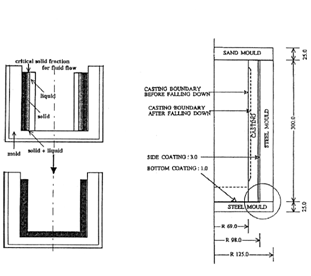

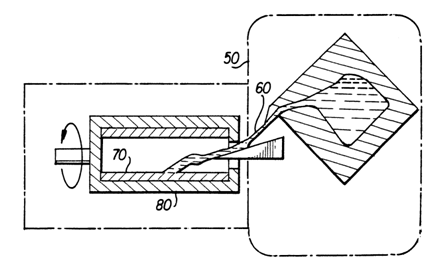

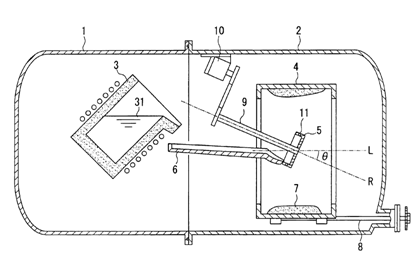

In true centrifugal casting procedure, the mould rotates around its axis. This axis of rotation might be vertical, horizontal or inclined based upon the shape of ending product. If the axis of rotation is horizontal it is known as horizontal centrifugal casting as illustrated in Figure 1 and if the axis is vertical or inclined this is called as vertical or inclined centrifugal casting as illustrated in Figures 2 and 3 respectively. In this the requirement of center core is totally eliminated. By this method Castings produced have true directional solidification. Due to directional solidification the casting therefore produced is defect free without any shrinkage that is prevalent in sand castings.

The rotation speed selection is extremely significant, mostly in the case of horizontal axis rotational speed plays a finite role. A speed lower than the needed causes slipping and raining of the metal that will not adhere to the mould surface. A speed higher than essential might cause hot tears on its walls.

(a) Vertical Centrifugal Casting

(b) Horizontal Centrifugal Casting

(c) Inclined Centrifugal Casting

Figure: True Centrifugal Casting