Semi-centrifugal Casting:

In the semi-centrifugal casting procedure the mould is not rotated as quickly as in the case of true centrifugal casting procedure. It is because only adequate force is needed to cause the molten metal to flow primary to the outer rims. In this procedure, mould is full from rim to hub not from bottom to top.

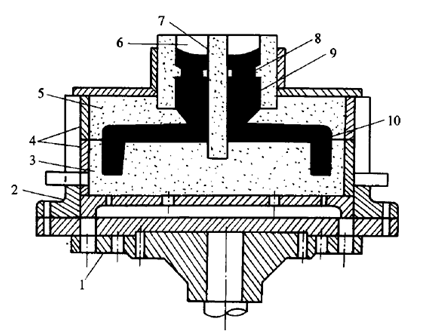

Figure: Semi-centrifugal Casting

This method is utilized for meeting big sized castings, that are symmetrical regarding their axis, e.g. gears, pulleys, spoke wheels etc. In this procedure, the metal is poured into central sprue that in turn is forced outwards to the rim through hubs from centrifugal force. For hollow sections dry sand or CO2 both core is utilized.