Machine Selection

Under utilization of costly processing equipment is a common characteristic of large industries. The under utilization might have two forms.

- Much of the machine time is idle and completely unproductive.

- Several of the parts assigned to a specific machine are far below the capacity of the machine.

Machines might be more fully utilized from both by utilizing effective scheduling as well as capacity technique utilization by grouping nearly matched parts into a part family. By utilizing a part coding system, same parts having similar feature dimension specification might be assigned to the part family, and machines equivalent to the minimum product specification might be selected instead of over specifying the processing.

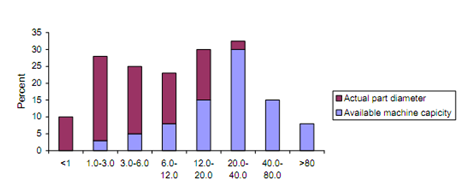

Diameter(inches)

Actual vs Available Machine Capacity

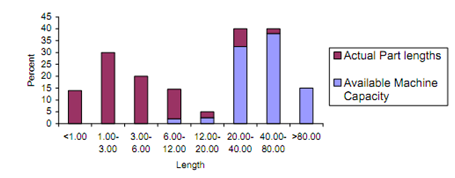

Figure: Comparison of a Turned-part Dimension as a Function of Machine Capacity

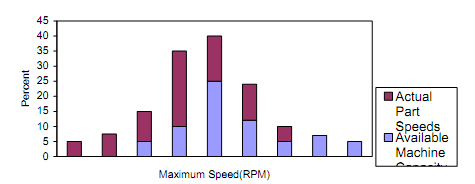

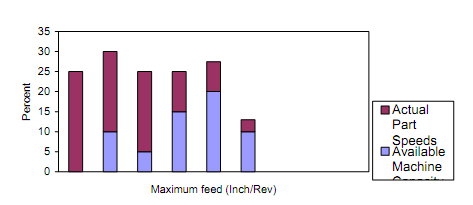

Given figure describes this phenomenon for lathe parts. In the figure it might be seen that only a few percent of the parts being machined needed the full lathe swing or length. Furthermore, the speed & feed capacity of the lathe might also be over specified in given figure.

.

.

Figure: Comparison of Maximum Speeds and Feeds with Maximum utilization