Models for Machine Cell and Part Family Formation

One of the primary utilization of coding system in manufacturing is to generate part families for efficient workflow. Efficient workflow might result from grouping machines logically so that material handling & setup might be minimized. The similar tools and fixtures might be used by grouping parts having similar operations. Because of this, a major reduction in setup results and also material handling among machining operations is minimized.

Family formation is depends on production parts or more specifically, their manufacturing feature. Components needs similar processing is grouped into the same family.

There is no rigid rule that might be applied to form families since a part family is loosely defined. A common rule for part family formation is that all parts in a family should be related that is all of parts in a family should require similar routing. A user might want to put only those parts having exactly the similar routing sequence into a family. Minimum change on the standard route is needed for such family members. Only, few parts shall qualify for family membership. Alternatively, if one groups all the parts requiring a common machine into family, large part families shall results.

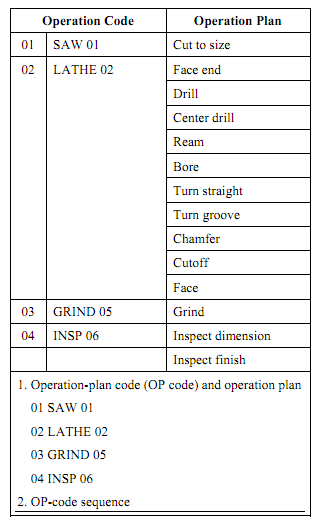

Before grouping might start, information associated to the design and processing of all existing components have to be gathered from existing part and processing files. Each of components is represented in a coded form, called as an operation-plan code (operation plan code,). An OP code represents a series of operations on a machine and/or one workstation.

Table : Operation Plan, OP Code, and Op-code Sequence

For instance, we might use GRIND05 to represent the sequence; load the workpiece onto the grinding machine, grind the workpiece, associate the grinding wheel, and unload the workpiece from the grinding machine. Operations shown by the Op code are called as an operation plan. This is not necessary that an OP code include all operations required on a machine for a component. It is utilized to represent a logical group of operations on a machine, so that a process plan might be represented in a much more concise manner. Such a representation is called as an OP code sequence. The major aim of an OP code is to simplify the representation of process plans. The simplified process plan might be stored and retrieved.