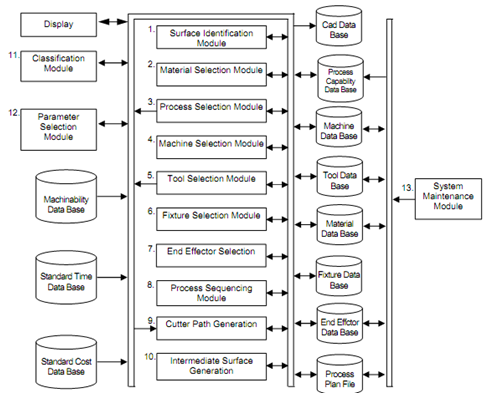

Structure of a CAPP System

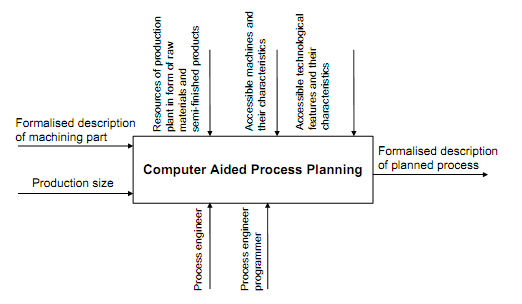

An ideal computer aided process planning system is shown in Figure 1. The system consists of several modules ranging from Feature extraction module to intermediate surface generation module. Each module may need execution several times to generate optimum process plan. The components taken into considerations in computer aided process planning are shown in Fig 2.

Fig1 : The Structure of a Computer Aided Process Planning System

The other data required for the generation of process plan are given below :

- Part list

- Annual demand

- Accuracy and surface needs

- Shop floor information - process capabilities

- Jigs, gauges, fixtures etc.

- Machining data

Figure 2 : Activities in Process Planning

By comparison with manual experience-based process planning, the use of computers in process planning also helps to achieve the following :

A. It can systematically produce accurate and consistent process plans.

B. It can decrease the cost and lead time of process planning.

C. The skill requirements of process planners are reduced.

D. It results in increased productivity of process planners.

E. The application programs such as cost and manufacturing lead time estimation and work standards can easily be interfaced.

Two major methods are utilized in computer-aided process planning: the variant CAPP method and the generative CAPP method.

Objectives

After studying this unit, you should be able to

- Know the concept of variant process planning system,

- Elaborate the generative process planning system, and

- Explain the knowledge-based process planning.