Knowledge Based CAPP System for Drawing

The architecture of a knowledge based CAPP system for drawing is quite similar to one discussed earlier for stamping. It essentially has the following functional modules :

- CAD modeling of parts

- Blank development

- Die Design

(i) Planning stages in drawing

(ii) Developing intermediate geometry

(iii) Die Layout

(iv) Design/Selection of punch/Dies

(i) Die Drawings

(ii) BOM

(i) Materials

(ii) Press/Tool Specifications

(iii) Decision Rules/Tables

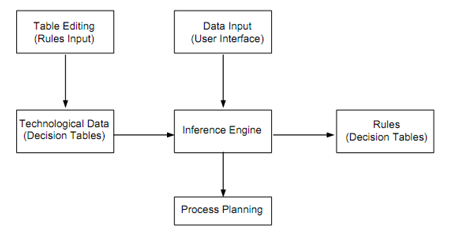

Figure: Knowledge Based CAPP System for Drawing

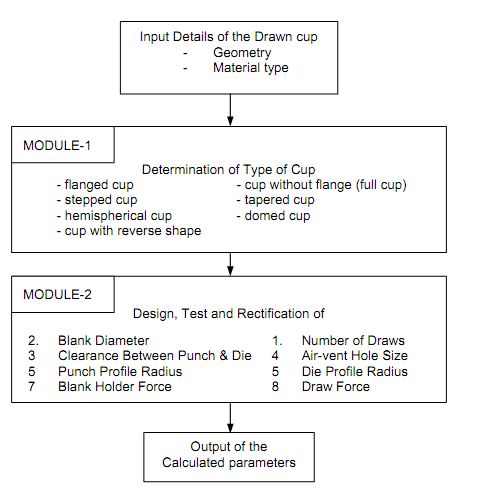

The CAPP system is knowledge based having an Inference engine and Rule/Data base as shown in Figure. The overall working of the knowledge based CAPP system is shown in Figure. It essentially is a two stage process as under.

Figure : Working of Knowledge Based CAPP System

Stage 1

Identification of the type of cup geometry to be formed from the CAD part model.

Stage 2

Design of Die Stages.

In what follows, important functional modules of the CAPP system are discussed.