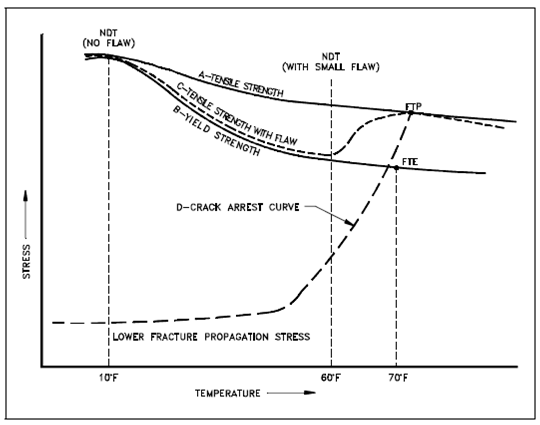

Stress- Temperature Curves:

One of the biggest concerns along with brittle fracture is in which it could occur at stresses well below the yield strength (stress corresponding to the transition from elastic to plastic behavior) of the material, given many conditions are present. Those conditions are: a flaw such as a crack; a stress of sufficient intensity to develop a small deformation at the crack tip; and a temperature low sufficient to promote brittle fracture. The relationship among these conditions is best elaborates using a generalized stress-temperature diagram for crack initiation and arrest as displays in Figure.

Figure: Stress-Temperature Diagram for Crack Initiation and Arrest

Above Figure described in which as the temperature goes down, the tensile strength (Curve A) and the yield strength (Curve B) rise. The increase in tensile strength, many times known as the ultimate strength (a maximum of increasing strain on to the stress-strain curve) is less than the increase in the yield point. At a few low temperatures, on the order of 10ºF for carbon steel and yield strength, tensile strength coincides. On this temperature and below, there is no yielding while a failure occurs. Therefore, the failure is brittle. The temperature at that the yield and tensile strength coincide is the NDT temperature.

While a small flaw is present, the tensile strength follows the dashed Curve C. On elevated temperatures the Curves A and C are identical. At lower temperatures, around 50ºF above the NDT temperature for material along with no flaws and the tensile strength curve drops to the yield curve and then follows the yield curve to lower temperatures. On that point where Curves C and B meet, there is a new NDT temperature. Thus, if a flaw exists, any failure at a temperature equivalent or below the NDT temperature for flawed material will be brittle.