Rotating Biological Contactors

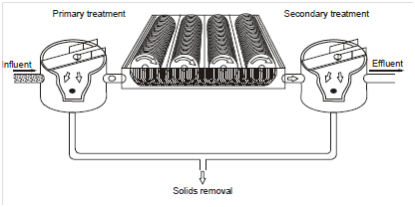

A rotating biological contactor (RBC) is an attached-growth biological procedure that consists of one or more basins in that large closely-spaced circular disks mounted on horizontal shafts rotate slowly by waste-water (Figure 19). The disks that are made of high-density polystyrene or polyvinyl chloride (PVC) are partially submerged in the wastewater, so that a bacterial slime layer forms on their wetted surfaces. As the disks rotate, the bacteria are exposed alternately to wastewater, from which they adsorb organic matter, and to air, from that they absorb oxygen. The rotary movement also permits excess bacteria to be erased from the surfaces of the disks and manages a suspension of sloughed biological solids. A last clarifier is needed to erase sloughed solids. Organic matter is degraded through means of mechanisms same to those operating within the trickling filters process. Partially submerged RBCs are used to carbonaceous BOD removal and combined carbon oxidation and nitrification or nitrification of secondary effluents. Fully submerged RBCs are used for denitrification.

Figure 19: RBC System Configuration

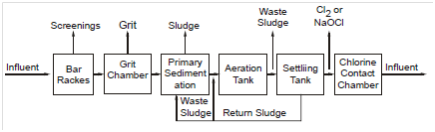

A typical arrangement of RBCs is shown in Figure 20. In general, RBC systems are divided into a series of independent states or compartments by means of baffles in a single basin or separate basins arranged in stages. Compartmentalization makes a plug-flow pattern, increasing whole removal efficiency. It also promotes a variety of conditions where different organisms could flourish to varying degrees. As the wastewater flows by the compartments, every following stage receives influent along with a lower organic content than the early stage; the system, therefore, enhances organic removal.

Figure 20: Typical Flow Diagram for RBC Units