Activated Sludge Process

The most generally applied biological treatment system is a suspended growth approach known the activated sludge process.

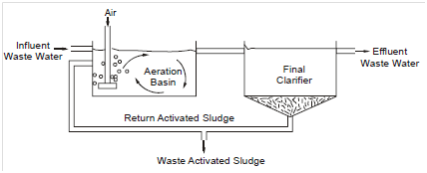

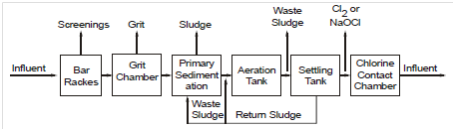

The activated-sludge procedure is an aerobic, continuous-flow system holding a mass of activated micro-organisms which are capable of stabilizing organic matter. Activated sludge systems are designed to manage intimate contact among the wastewater, a huge population of bacteria and oxygen. The micro-organisms are "activated" for rapid uptake of new substrate, therefore the term activated sludge. The procedure consists of delivering clarified wastewater, after primary settling, into an aeration basin whereas it is mixed along with an active mass of micro-organisms, mainly bacteria and protozoa, that aerobically degrade organic matter into water, carbon dioxide, new cells and another end products. The bacteria included in activated sludge systems are primarily gram-negative species, involving carbon oxidizers, nitrogen oxidizers, non-floc formers and floc formers, or aerobes and facultative anaerobes. A protozoon, for their part, involves flagellates, amoebas and ciliates. An aerobic environment is maintained in the basin through means of diffused or mechanical aeration, that also serves to keep the contents of the reactor (or mixed liquor) completely mixed. After an exact retention time, the mixed liquor passes into the secondary clarifier, whereas the sludge is permitted to settle and a clarified effluent is generates for discharge. The procedure recycles a portion of the settled sludge back to the aeration basin to manage the needed activated sludge concentration (Figure 12). The procedure also intentionally wastes a portion of the settled sludge to manage the required solids retention time (SRT) for effectual organic removal.

Figure 12(a) : Typical Flow Diagram for an Activated-sludge Process : Aeration Tank and Secondary Clarifier

Figure 12(b) : Typical Flow Diagram for an Activated-sludge Process : Sequence of Wastewater Treatment Units Including Aeration Tank and Secondary Clarifier

Control of the activated-sludge process is important to maintain a high treatment performance level under a wide range of operating conditions. The principal factors in procedure control are the subsequent:

(a) Maintenance of dissolved oxygen levels within the aeration tanks.

(b) Regulation of an amount of returning activated sludge.

(c) Control of a waste activated sludge.