Babbitts

The alloys of tin, copper, lead and antimony are called babbitts. The tin provides the hardness and compressive strength of babbitts, copper makes them tough, antimony prevents shrinkage while lead contributes to ductility. Bearing liners are extensively made in babbitts for their better antifriction properties than bronzes.

When Babbitt is backed up a solid metal of high compressive strength it gives good service under high speeds, heavy pressure, impact loads and vibrations. The backing material could be bronze or steel. A thin layer of high-tin Babbitt thoroughly fused to a tinned bronze or a steel shell has exceptional load carrying capacity and impact strength. In case of cast iron bearings the Babbitt in anchored in place by dovetail slots or drilled holes, because Babbitt does not fuse with cast iron. Babbitt bearing linings of dependable strength and life are made by pouring molten material into bearing, allowing solidifying and fusing thoroughly and then machining to finished sizes. While the melting point of Babbitt varies between 180 to 245oC, depending upon composition, the pouring should be done when metal is in fully fluid state. For example, SAE 10 babbitt has a melting point of 223oC, it should not be poured below 440oC.

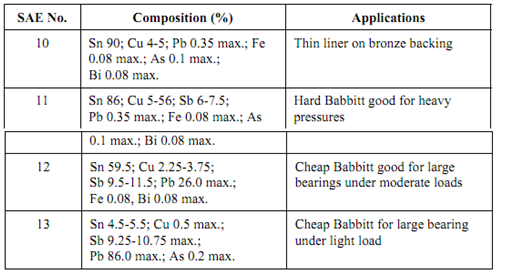

Some Babbitt materials are described in Table .

Table: Babbitts (White Bearing Metals)