Choosing construction material:

It is not possible to eliminate the background altogether. However, it may be minimized by extensive use of lead/steel or concrete shielding, by choosing construction material with low contamination, by the use of anticoincidence counters and pulse height discriminator as follows:

1. Massive Lead/Steel Shielding: A thick wall of lead or steel may be assembled around the detector so as to reduce the background considerably. It has been estimated that 2" thick lead bricks may reduce the background by one fourth. For this purpose 4"x6"x2" lead bricks are commonly available and a cage may be fabricated around the detector.

2. Anticoincidence Circuit Shield: It consists of an umbrella of several counters surrounding the main counting unit such that if both counters detect a count simultaneously then it is rejected. Such rejection occurs when the source of radiation lies external to the source.

3. Pulse Height Discrimination: This method is useful with proportional counter or scintillation detector in differential mode. It is based on the principle of sorting pulses produced by a detector according to its size and accepting only those pulses, which are produced by the sample.

Therefore, for all routine work, background activity should be measured under the operating conditions and subtracted from the observed measurement for the sample, taking proper care to treat the data statistically. In order to make background counts statistically significant, it should always be counted for a long period, say 1-2 h or even more. As a result, it is more convenient to employ counting rates. Thus, corrected count rte (Rc) may be represented as

Rc = Rx - Rb

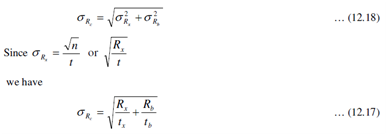

where, Rc, Rx and Rb are the count rates for the sample and the background, respectively. The standard deviation of the corrected count rate can be obtained by the equation

As you could realize, background correction is much more complicated than blank correction in common chemical or instrumental method.