Automatic Tool-changing Mechanisms on Turning Center

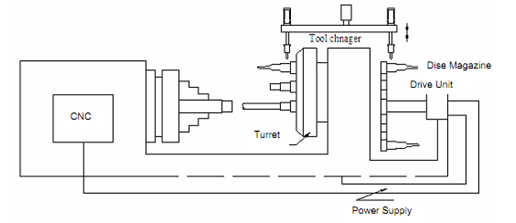

Cutting units can be stored in either a drum or a disc sort of storage device. A common instance of the storage facilities and their automatic tool-changers is displayed in diagram. The rotary tool-changer swivels among the tool magazine and the machine's turret. Each gripper can rotate by 90°, to deliver tools to the front face of the turret. The tool-changer at the same time removes the cutting tools from the disc magazine and the turret and then it rotates through 180°. The new tool is delivered to the turret and precisely positioned in the correct orientation, whilst the used tool is changed in its correct turret position for either again use or replacement. The tool-changer arm is withdrawn from the working area of the machine and starts the cutting cycle. A gantry-type of tool-changer along with a twin-gripper assembly can be utilized for high-speed tool-changing where space in the area of the machine is limited.

Figure: CNC Turning Machine with Integrated Disc Magazine for Automatic Tool Changing

In this design, the gripper assembly as well rotates though 90° to deliver tools to the turret's periphery. The main benefit of using this type of tool-changer is that it can be fitted to a machine tool along with very little modification and it keeps the working area free from any mechanisms which might get affected by swarf or hit by the machine tool's moving parts. The disc-type turret magazine that is mentioned above has "random-access" capability. This means that the tool-changer has totally free access to any tool in the store providing an almost immediate delivery to the turret. If company needs even more versatility from the automation of block tooling system, it is as well possible to change the disc turret automatically and accordingly, the tool-storage capacity approaches to infinity. The benefit of using this universal tool-changing mechanism is that they are designed on the modular principle and can be fitted to any configuration a company needs permitting for higher degree of customization.

The drum-type tool-storage facility is utilized in conjunction along with a gantry-type loading configuration. The rotary drum-type holder allows a continuous supply of cutting units over long periods of not attended machining in similar manner as with the disc turret. When first setting of the machine for a latest family of work pieces, the magazine racks can be simply substituted along with new one, which holds other types of tools. The cast iron drum contains the rotating magazine holder assembly and it encloses the interior working parts. This drum is mounted centrally on z column and runs freely on two bearing. A locking mechanism that is attached to the drum and hinge plates for mounting of either five or ten cutting-unit magazines depending upon the capacity of magazine holder. The drum can easily be eliminated so that the interior working parts are accessible. The tool-actuator mechanism is stationary inside the rotating magazine holder. This mechanism transports the cutting units from or into the magazines. While a specific tool-cutting unit is called, the drum magazine is indexed into position before the tool is energized. After that the actuator will load or unload the gripper. The gripper is attached to transportation mechanism specifically to a gantry robot and is taken to the machine-tool magazine. "Sister tooling" can be utilized for heavily utilized cutting tools that is why the system have a large and versatile cutting capacity on the shop floor mainly if powered tooling is also incorporated into the system as mentioned before. Their versatility can be further improved if gantry robot is designed to include such types of features as such trigger probing and the capacity to load and unload the work-piece. This level of sophistication along with and work loading coupled to a 'probing ability' is almost the state of art but not quite so totally automated machine tools where chuck jaws for holding different work holding needs can be offered or a complete chuck-changing facility by using a gantry robot is probable as listed by some machine tool builders. While machines with sophisticated specifications are used either as 'stand alone' machines or as parts of flexible manufacturing system, the throughput of work and range of applications are considerably high. While coupled with a high utilization system having many shifts and pay back period after that time for return on the investment of machine tool is much shorter. The level of investment needed to incorporate all of the features explained above is considerable and is only possible when a company has a supposed volume of work which justifies the cost. An alternative approach that might be appropriate for medium to large-batch situations in which the product line is diverse and calls for a specific amount of flexibility in coping along with the production demands. Here, the conventional turning- centre turret has quick-change tooling supplied through a chain-type tooling carousel that can carry almost 20 additional tools that may be used. This tooling configuration by automatic tool clamping in the turret is within the reach of most budgets and significantly expands the machine's capabilities for coping with a much more diverse range of jobs.

To reiterate before statements, whichever the configuration and whatever level of sophistication one requires from a machine tool, it should be apparent which quick-change tooling expands the tooling potential vastly, even as reducing non-productive cycle times. It should be enthusiastically referred as an alternative to conventional tooling. It may be used on other machines for example CNC machines or even conventional machines just by changing the adaptor. If a company cannot afford the whole system, it should experiment with just in a few units to gain experience in their use - bearing in mind, certainly, that the full production savings will only result while a whole system is used in an effective manner. The automatic tool changing system is a sophisticated, well-tried and time tested tooling, comprising large scale industrial usage. Just once the tool starts to degenerate (probably through extraneous circumstances), the productive capability is lost. At the least, there is a requirement to protect the tool from the little chance of failure by using some form of tool-condition monitoring system.