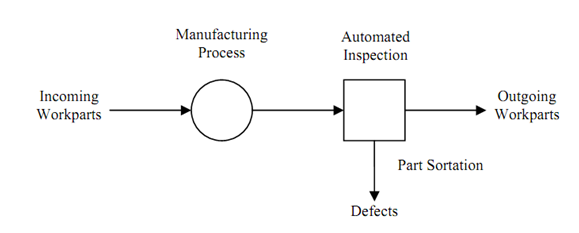

Parts Sortation

Here, parts are sorted on the basis of quality level & classified as rejected or accepted part. There might be more than two levels of quality suitable for the process (for example, reworkable, acceptable and scrap). Sortation and inspection might be accomplished in various ways. One option is to both inspect and sort at the similar station. Other installation situated one or more inspections along the processing line, with a single sortation station near the ending of the line. Inspection data are evaluated and inspections are put forth to the sortation station mentioning what action is needed for each part.

Figure: Action Step Resulting from Automated Inspection : Sortation of Parts into Two or More Quality Levels