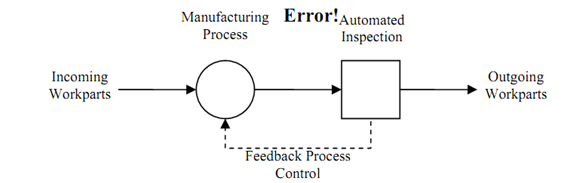

Feedback Process Control

In the inspection operation, data are feedback to the manufacturing procedure responsible and the similar is evaluated. The motive behind the feedback is to permit compensating adjustments to be made in the process to decrease variability and develop quality. If the output of process begins drifting toward the high side of tolerance (for example tool wear might cause a part dimension to enhance over time), adjustment might be made in the input parameters to bring the output back to the nominal value. In this mode, average quality is maintained in a smaller variability range than is possible with sampling inspection methods. As a consequence, process capability is improved.

Figure: Action Step Resulting from Automated Inspection : Feedback Process Control