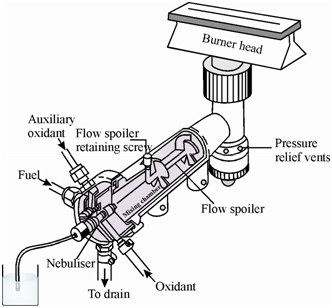

Premix or Lundegarh burner:

Within the premix burner, fuel and oxidant are by mixed within the burner housing before they leave the burner ports and enter the primary-combustion or inner zone of the flame. In these categories of burner, the solution of the analyte is aspirated along with the help of a nebuliser from the sample holder into the mixing chamber in that the fuel gas is also introduced. The larger drops are stopped through baffles within the mixing chamber and are drained off. Pressure and density fluctuation of the aerosol because of atomisation are smoothened in the mixing chamber and combination of aerosol, fuel gas and oxidant burns to yield stable noiseless flame.

The solvent of the smaller droplets evaporates partly first within mixing chamber, then in the conduit of the burner and at last in the flame. Just drops of a certain size could reach the burner and are fully burnt. Therefore, the efficiency of the premix burner is low and only 5% of the sample reaches the burner. An efficiency of this burner has been improved by putting an impact bead instantly after the nebuliser. An impact bead has the effect of breaking up huge droplets as they come out from the nebuliser, thereby raising the number of smaller droplets and the efficiency of nebulisation. A schematic figure of a premix burner is given in Figure.

Figure: Schematic diagram of a premix burner