Variant Approach

A variant system is much simpler than a generative approach; however it can require more human interaction. It must be realised that all CAPP systems need someone to input the part specifications (features, shape, dimensions, tolerances, instructions and so on.).

Variant CAPP systems are designed to use the fast storage & retrieval capabilities of a computer and to give an interactive environment among the planner and the computer. This kind of system is built up so that a planner with restricted computer knowledge can effectively prepare a process plan. Therefore, the planner is prompted for the essential data, and the inputs are edited. If errors are find out, the user is prompted to correct the erroneous entry.

A variant system needs a database containing standard plans. Standard process plan for a family of parts consists of all instructions (that means operations, tools, etc.) that would be involved in a process plan for any part with in that family. Group technology concepts are utilized to form part families and there from a standard process plan is created for each of these families and stored in the computer.

The process planning task for a new part starts with coding and classification of the parts in a part family using GT. The standard process plan for this family might then be retrieved from the computer. As this plan contains instructions for all parts in this family, some editing can be required for a specific part. Hence, variant systems provide editing programs to facilitate this procedure. Frequently, very little editing is required, because the new plan is a variant of the standard process plan; and significantly greater consistency in plans is obtained. After editing, the plan might be stored and/or printed out.

If the part being planned may not be classified into an existing family of parts, the planner might develop a new standard process plan by using interactive computer programs.

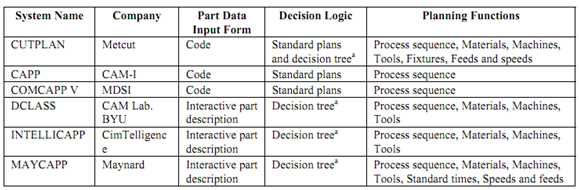

One of the first variant systems developed was termed as CAM-I. Initial developments were completed in the year 1976 under the sponsorship of Computer Aided Manufacturing- International to show the feasibility of CAPP systems. It was so successful that various companies modified this system to meet their specific needs. Given table provides a summary of some of the retrieval type CAPP systems that are available commercially.

Table: Some Commercial Variant Process Planning Systems