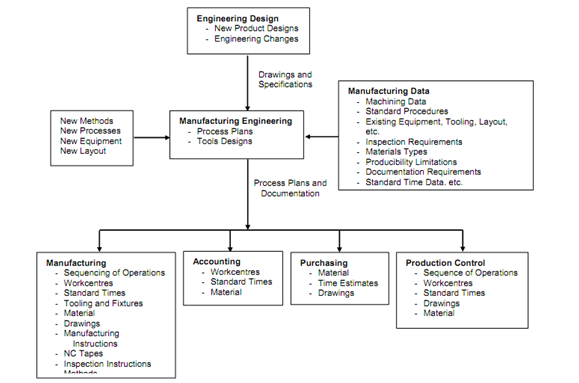

Process Planning Information Flow

It has been more than 20 years since primary noticeable efforts to automate process planning by using computers began. In this period mostly two approaches have emerged. The first one, which is called as variant approach, relies on standard plans developed from previously manufactured parts. The second approach that is called generative involves the generation to process plans automatically without referring to existing plans of previously manufactured components.

At the similar time, some CAPP system developers have attempted to combine some features of both approaches forming another category what is called as semi-generative CAPP.

Since a bridge among CAD & CAM, CAPP relies on good interfaces among these systems (or integration of such systems) to function effectively. At present, almost all CAPP systems employ manufacturing features for part description. Various approaches have been developed to extract the manufacturing features of a part from CAD data.

Figure Process Plan Information Flow