Aluminum

Al in %age of 1 to 3 in nitriding steels is added to enhance harness by way of forming Al nitride. 0.01 to 0.06% Al added during solidification produces fine grained steel castings.

We may also correlate specific desired properties along with alloying elements. They are mentioned as given here:

(a) Harden capability is improved by addition any or more than one of the following. Si, Mn, Nickel, Chromium, Mo, B, W.

(b) Toughness is the capacity to absorb energy before fracture increases along with addition of Si and Nickel.

(c) The presence, of Chromium, W and Mo helps steel to retain strength at high temperatures.

(d) Chromium, Mo and W also help enhance resistance against corrosion.

(e) Wear resistance of steel increases when alloyed with Chromium, Mo, W and Vanadium.

(f) The impact strength at low temperature improves because of Ni.

(g) Copper helps steel achieve better resistance against atmospheric corrosion.

(h) Surface harden ability is enhanced by addition of Al

(i) V helps increase fatigue strength of steel.

(j) Steels along with S, P and lead have better machine ability.

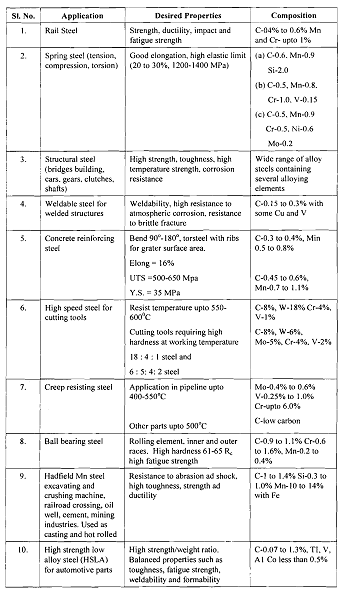

In the given table application, desired properties and composition of some alloy steels describes:

Table of application of alloy steel