Freeze Drying:

Freeze drying is a successful procedure of liquid separation through a product in a frozen state, attained by sublimation under vacuum. The sublimation serves to get a product that achieved even its volatile components and primary quality, and the vacuum is utilized to maintain the physical state like freezing and to direct the vapour flow. Currently, the major problems to the application of the procedure generally are; (a) the comparatively high cost of the freeze-dried manufactured by sublimation- dehydration because of high vacuum, (b) extremely low temperature refrigeration to pre- freeze the product & then to compress the sublimated vapour, (c) the complexes operational control & (d) the long throughout of the freeze-drying time. However characteristically, the cost is not the estimating factors for the product of certain products including blood plasma, life-saving medicines likes' gamma-globulin, and high value food products like shrimp, mushrooms prawns, etc.

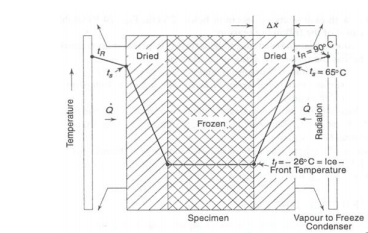

Given figure illustrate a model of the freeze-drying procedure with radiant heating. The profile illustrates the temperature distribution.

The dehydration occurs into a vacuum chamber. In the chamber the pressure ought to be maintained below the triple-point pressure, generally below 5 mm Hg, or else the manufacture will begin to thaw.

Temperature Distribution during Freeze-Drying of a Specimen with Radiant Heating