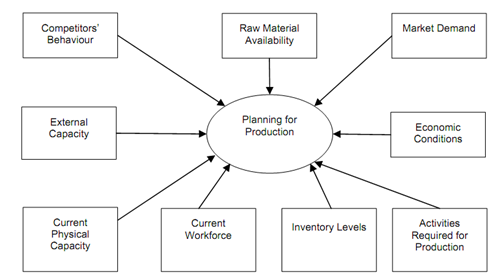

Aggregate Production Planning Environment:

Figure illustrates the internal and external factors that constitute the production planning environment. Generally, the external environment is outside the production planner's direct control, but in some of the firms, demand for the product may be managed. Through close cooperation between marketing and operations, promotional activities & price cutting may be utilized to build demand during slow periods. Conversely, when demand is strong, promotional activities can be curtailed and price rose to maximize the revenues from those products and services that the firms have the capacity to provide.

Complementary products may work for firms facing cyclic demand fluctuations. For example, lawnmower manufacturer shall have strong demand for spring and summer, but another product may have weak demand during spring and summer (for instance, snowmobiles, snow blowers, or leaf blowers). With services, cycles are more frequently measured in hours than months. Restaurants with strong demand during lunch and dinner will frequently add a breakfast menu to increase demand during morning hours.

But even so, there are limits to how much demand may be controlled. Ultimately, the production planner must lie with the sales projections and orders promised by the marketing function, leaving the internal factors as variables that may be manipulated in deriving a production plan. A new approach to facilitate managing these internal factors is called as accurate response. This entails refined measurement of historical demand patterns blended with expert judgment to determine when to begin the production of particular items.

The key element of the approach is obviously recognizing those products for which demand is relatively predictable from those for which demand is relatively unpredictable.

The internal factors themselves vary in their controllability. Current physical capacity (plant and equipment) is usually closely fixed in short run; union agreements often put constraints on what can be done in changing the workforce; physical capacity may not always be increased; and top management might limit the amount of money that can be tide up in inventories. Still, here is always some flexibility in managing these factors, and production planners can implement one or a combination of the production planning strategies discussed here.

Figure: Required Inputs to the Production Planning System