Tool Life Equation

At low cutting speeds, the tools have higher life but the productivity is low, and at higher speeds the productivity is high but tool life is less. This fact has inspired Taylor in formulating the relationship of tool life and the cutting speed. After experimentation he proposed the following formula for tool life.

V Tn = C

Where

n = Constant for tool material, V = The cutting speed, m/min,

C = Machining constant, T = The tool life in min

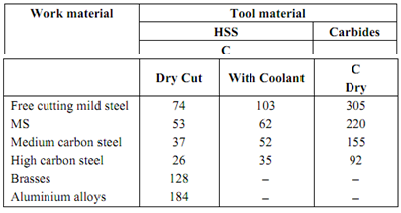

Table 3 : Constant C for Taylor's Equation

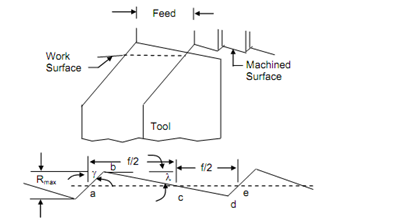

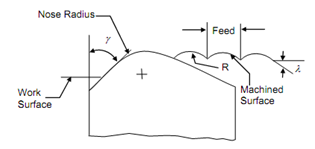

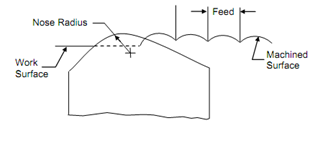

As this formula doesn't take into account all the effecting parameters, e.g. feed, depth of cut, etc. (as shown in Figures 6(a) and (b) for sharp cutting tools and tools having a nose radius respectively) many researchers have modified this formula.

Figure 6(a): Surface Profile Obtained by Sharp Cutting Tool

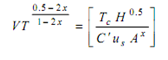

Equation 1

T θB = C

Equation 2

Where

H = Specific heat x thermal conductivity, θ = Mean tool chip interface temperature,

A = Area of cut, us = Specific cutting energy/unit cutting force, and

C and x are constants.

Equation 3

VT n f n1 , d n 2 = C

where

f = Feed, mm/rev, d = Depth of cut, and

C = Constant.

Figure 6 (b) : Surface Profile Obtained by a Cutting Tool having a Nose Radius