Starting a Synchronous Motor:

A synchronous motor might be beginning through a DC motor on a general shaft. AC current is applied to the stator windings when the motor is brought to synchronous speed. DC motor now acts as a DC generator and supplies DC field excitation to the rotor of the synchronous motor. The load might now be placed on the synchronous motor. Synchronous motors are more frequently begins through means of a squirrel-cage winding embedded within the face of the rotor poles. The motor is then begin as an induction motor and brought to ~95% of synchronous speed, at that time direct current is applied and the motor starts to pull into synchronism. The torque needed to pull the motor into synchronism is known as the pull-in torque.

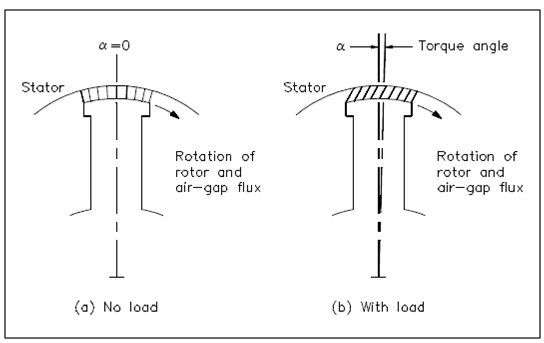

As we already have knowledge, the synchronous motor rotor is locked into step along with the rotating magnetic field and must continue to operate at synchronous speed for all loads. In During no-load conditions, the middle lines of a pole of the rotating magnetic field and the DC field pole coincide. Since load is applied to the motor that is a backward shift of the rotor pole, associative to the stator pole. There is no change in speed. The angle among the rotor and stator poles is known as the torque angle (α).

Figure Torque Angle

If the mechanical load on the motor is raise to the point where the rotor is pulled out of synchronism (α≡ 90o) than the motor will stop. The maximum value of torque in which a motor could develop without losing synchronism is known as its pull-out torque.