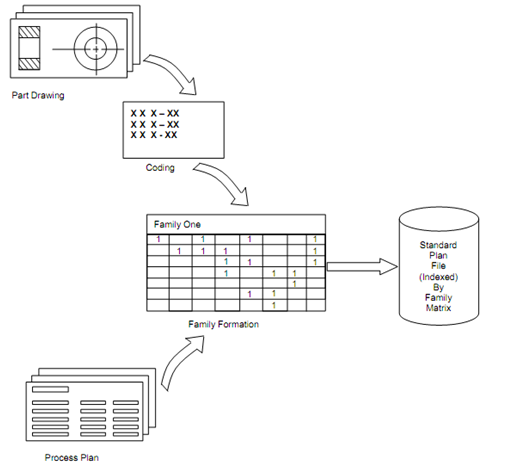

Preparatory Stage

The preparatory work is required when a company first starts implementing a variant system. Throughout the preparatory stage, current components are coded, classified & subsequently grouped into families. After the coding is completed, part families are formed. A family matrix is then constructed for each part family. Due to large number of components involved, a computer must be used to construct part family matrices. The next step is to set up standard process plans for part families. By summarising the process plans, a set of standard operation plans (OP Plans) might be identified

Figure: Preparatory Stage

An operation plan contains a sequence of manufacturing operations that are generally performed together in a work station. An identifier, OP Code is assigned to every OP Plan. A standard procedure plan is written in terms of OP Codes & OP Plans. Standard plans are then stored up in a database and indexed by family matrices.

The preparation stage is labour intensive. Whatsoever is prepared for utilize in a specific shop can only be utilized for that shop.