Approaches to Process Planning for Machining Operations

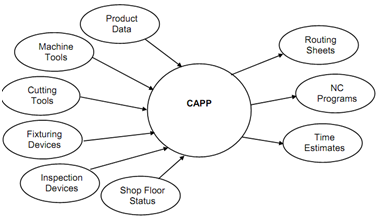

Process planning involves determining the essential manufacturing processes & their sequence to produce a given part economically & competitively. In terms of machining processes, the main process planning activities are the interpretation of manufacture design data. Selection of machining processes, determination of production tolerances, determination of datum surfaces and fixtures, selection of inspection devices, sequencing of operations, determination of proper cutting conditions, calculation of total production times and generation of process sheets and NC data as illustrated in given figure.

Figure: Inputs and Outputs of a CAPP System for Machined Parts