Torsional equation:

Derive the Torsional equation T/J = Π /R = Gθ/L

Or

Derive an expression for the shear stress in shaft subjected to a torque.

Sol.: Assume,

T = Maximum twisting torque or twisting moment

D = Diameter of shaft

R = Radius of shaft

J = Polar moment of Inertia

τ= Maximum Permissible Shear stress (Fixed for given material)

G = Modulus of rigidity

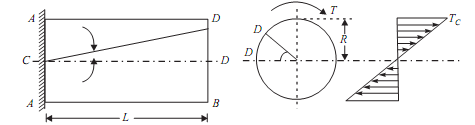

θ= Angle of twist (Radians) = angle D'OD L = Length of shaft.

?= Angle D'CD = Angle of Shear strain

Than Torsion equation is: T/J = τ/R = G. θ /L

Let the shaft is subjected to a torque or twisting moment 'T'. And hence every C.S. of this shaft will be subjected to shear stress.

Now distortion at the outer surface = DD'

Shear strain at outer surface = Distortion/Unit length tan? = DD'/CD

i.e. shear stress at the outer surface (tan? ) = DD'/L or = DD'/L ...(i)

Now DD' = R.θ or ?= R . θ /L ...(ii)

Now G = Shar stress induced/shear strain produced

G = τ/(R. θ /L);

or; τ/R = G. θ /L ...(A);

This equation is called Stiffness equation.

Hear G, θ , L are constant for a given torque 'T'. That is proportional to R

If τ r be the intensity of shear stress at any layer at a distance 'r' from canter of the shaft, then;

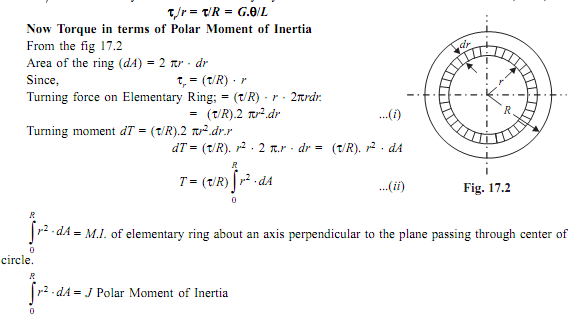

Now from equation (ii) T = ( τ/R) J

or τ/R = T/J; ...(B)

This equation is called as strength equation

The combined equation A and B; we get

T/J = τ/R = G. τ/L

This equation is called as Torsion equation.

From the relation T/J = τ/R ; We have T = τ.J/R = τ .ZP

For the given shaft IP and R are constants and IP/R is thus constant and is called as POLAR MODULUS(ZP). of the shaft section.

Polar modulus of section is thus measure of strength of shaft in the torsion.

TORSIONAL RIGIDITY or Torsional Stiffness (K): = G.J/L = T/θ