Petrol or gasoline can be synthesized by following three methods:

1. Polymerisation

2. Fischer - tropsch method

3. Bergius process

polymerisation

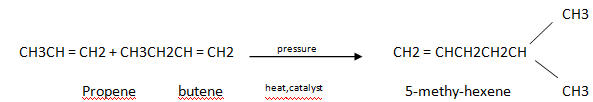

In this method, smaller molecules of hydrocarbons are combined to form heavier molecule resembling gasoline.

There are two types of polymerisation.

(a) Thermal polymerization: thermal polymerisation is carried out at temperature about 500-6000C and pressure about 70-350 kg/cm2 .

(b) Catalytic polymerization: it is carried out at a lower temperature of 150-2000C, in a low-pressure and in presence of catalyst like phosphoric acid. The rate of reaction is increased. The gasoline obtained is of improved quality and possess high antiknock properties than the gasoline obtained from thermal polymerisation process.

1.15.2 Fisher – tropsch method

It is a catalytic reduction of CO and H2 to get straight chain alkane and olefins.

A mixture of water gas (CO + H2) with excess of hydrogen is passed through the purification chamber. The lron oxide and mixture of Fe2O3 & Na2CO3 containing chambers removes the sulphur and sulphur compounds. The mixture after removal of sulphur and its compounds are forced to the catalyst chamber. Mixture of cobalt (100 part), thoria (5 parts), magnesia (8 parts) and kieselguhr (200 parts) acts as catalyst.

At a temperature of about 200-2500C , reaction takes place to form saturated and unsaturated hydrocabons. Reactions are exothermic

nCO + 2nH2 CnH2n + nH2O + heat

nCO + (2n + 1) H2 CnH2n+2 + nH2O + heat

The products are led to a cooler, where gasoline and heavy oil are obtained. Heavy oil can be further cracked to get gasoline.

1.15.3 berguis process

This process is used to convert low grade coals as bituminous coal and lignites into liquid and gaseous fuel by hydrogenating them in presence of catalyst (Ni or tin oleate).

In this process, the powdered coal is mixed with heavy oil and the catalyst (Sn or Ni oleate) heated with hydrogen for 1 1/2 hr at a temperature of 4500 C and pressure of 250 atm in the convertor. The gases are fed to condenser where crude oil is obtained. This crude oil is fractionated to get gasoline, middle oil and heavy oil. Heavy oil is recycled for forming paste, and middle oil is cracked to get gasoline.