Differentiate between strength of material and engineering mechanics

Sol.: Three primary areas of mechanics of solids are statics, dynamics and the strength of materials.

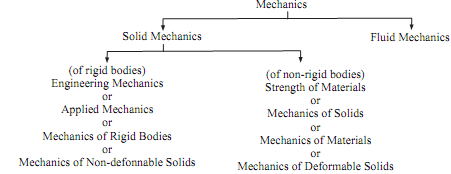

Strength of materials is a branch of 'Solid Mechanics'. The other significant branch of solid mechanics is Engineering Mechanics: statics and dynamics. While 'Engineering Mechanics' deals with the mechanical behavior of rigid (non deformable) solids subjected to the external loads, 'Strength of Materials' deals with the mechanical behavior of non rigid (or deformable) solids under the applied external loads. It is known by other names also such as Mechanics of Materials, Mechanics of Deformable Solids and Mechanics of Solids. Summarily, a study of solid mechanics is grouped as follows.

As none of the known materials are rigid, thus the studies of Engineering Mechanics are based on the theoretical aspects; but because all the known materials are deformable, studies of strength of the materials are based on realistic concepts and practical footings. The study of Strength of Materials assists to design engineer to select a material of known strength at the minimum expenditure.

The studies of Strength of Materials are applicable to almost all the types of machine and structural components, all the varieties of materials and all the shapes and cross sections of components. There is numerous varieties of components, each behaves differently under different loading conditions. These components can be made of high strength steel, ductile aluminium, brittle cast iron, low strength plastic, flexiable copper strip, or stiff tungsten.