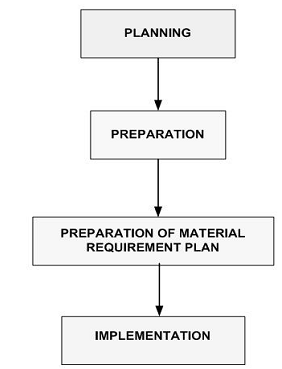

Steps in production process

A project whether it is the development of Fast Moving Consumer Goods (FMCG) product, a Parma product or any other product, generally follows the standard model with customisation for specific industry depending on its nature. It is a statement of the broad direction of the firm, kinds of business and product lines it proposes to take up.

There are various stages involved in it. They are illustrated in the figure:

Let us now discuss each of these stages in detail.

1. Stage 1 - Planning: The objectives mentioned in the strategic plan, act as a guideline for preparation of production plans. The production management prepares plan for quantities of each product group, resources of equipment, labour and material required and the availability of resources. Planning gives the long-range forecast and general directions as to how the company plans to achieve its objectives. It is prepared with the participation from marketing, finance, production and engineering teams. This plan is prepared for a time horizon of a year without many details.

2. Stage 2 - Preparation: It is of master production schedule. This is a plan for production of individual items at component level. This is prepared based on sales orders, inventories and existing capacity. Manufacturing and purchase lead times are important considerations in preparation of master production schedule. The planning horizon for this plan could extend beyond a financial year as the product mixes do not undergo a drastic change over this period.

3. Stage 3 - Preparation of Material Requirement Plan: Here, the actual quantities to be produced are decided with minute details. The role of manufacturing and purchase lead times is an important consideration here. The planning horizon for this activity generally extends from 3 to 18 months.

4. Stage 4 - Implementation: Purchasing and production activity controls the implementation phase of a production system. Purchasing takes care of all raw material and purchase part supplies to the plant, thus ensuring uninterrupted supply. Production activity controls the manufacturing activity within the plant. This ensures free flow of Work In Progress (WIP) ensuring steady supply of inputs, at assembly stage for uninterrupted despatch of finished goods to customers. The planning horizon in this stage is very short and could be as small as days.

All these activities integrated with sales and operations planning need to handle large amount of data involving a number of calculations. Thus, the strategic business plan incorporates marketing, finance and production. Manufacturing should meet the required demand, financing should concur with other functions from financial point of view, and marketing must ensure that its plans are achievable. The result of integrated approach for all these was the evolution of manufacturing planning and control system, which interacts with all the related functions in the system. This integrated planning and control system is called manufacturing resource planning-MRP II to distinguish it from materials requirement plan.