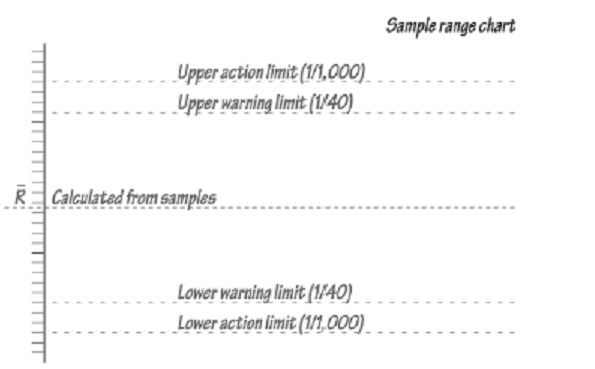

Sample Range Chart - Control Charts for Variables

Whilst the sample mean chart provides control over the process setting, it provides no protection from change (increase) in the standard deviation of the process output. The second control chart (shown here) provides this by means of control limits set out from the average sample range (¯R) , determined when the process was stable.

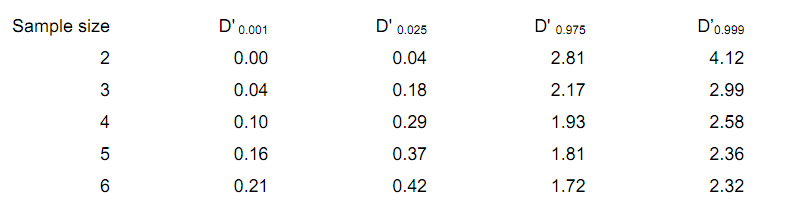

Again, the control limits are established as 1-in-40 warning and 1-in-1000 action limits. They are determined by multiplying the average sample range (¯R) by the appropriate D' coefficient from the table below.

Upper action limit = D'0.9999 ¯R

Upper warning limit = D'0.975 ¯R

Lower warning limit = D'0.025 ¯R

Lower action limit = D'0.001 ¯R

In practice, the lower control limits are often omitted, the reasoning being that exceptionally low range values represent welcome consistency. However, such low-probability results are unlikely to be produced by a stable process, and may, in fact, be an indication that the measurements are incorrect.