Properties of Stones

The following properties of the stones should betake into account before choosing them for engineering works:

Structure: The structure of the stone can be stratified (layered) or unstratified. Structured stones should be simply dressed and appropriate for super structure. Unstratified stones are hard and complicated to dress. They are preferred for the foundation works.

Density: Denser stones are stronger. Light weight stones are weak. Therefore stones having specific gravity less than 2.4 are considered unsuitable for buildings.

Appearance: A stone having uniform and attractive color is durable, if grains are compact. Granite and Marble get very well appearance, when polished. Therefore they are used for face works in buildings.

Texture: Fine grained stones with homogeneous distribution look attractive and therefore they are used for carving. Such stones are typically strong and durable.

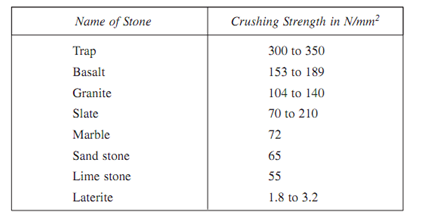

Strength: Strength is an essential property to be looked into before choosing stone as building block. According to Indian standard code recommends, minimum crushing strength of 3.5 N/mm2 for any particular building block. Given table shows the crushing strength of many stones. Due to non-uniformity of the material, generally a factor of safety of 10 is used to discover the permissible stress in a stone. Therefore even laterite can be used safely for a single storey building, because in such type of structures expected load can hardly give a stress of 0.15 N/mm2. Still in stone masonry buildings care should be taken to ensure the stresses when the beams (Concentrated Loads) are placed on laterite wall.

Table for crushing strength of common building stones

Hardness: It is an essential property to be considered when stone is used for pavement and flooring. Coefficient of hardness is to be found by conducting test on standard specimen in Dory's testing machine. For road works coefficient of hardness should be at least 17. For building works stones having coefficient of hardness less than 14 should not be used.

Percentage wear: It is measured by attrition test. It is an essential property to be considered in choosing aggregate for road works and railway ballast. A good stone will not show wear of more than 2%.

Porosity and Absorption: All the stones have pores and therefore absorb water. The reaction of water having material of stone causes disintegration. Absorption test is referring as percentage of water absorbed by the stone when it is immersed under water for 24 hours. For a good stone it ought to be as small as possible and in no case more than five.

Weathering: wind and Rain cause loss of good appearance of stones. Therefore stones with good weather resistance should be used for face works.

Toughness: The resistance to impact is known toughness. It is resolute by impact test. Stones having toughness index more than 19 are preferred for road works. The toughness index 13 to 19 is considered as medium tough and stones having toughness index less than 13 are poor stones.

Resistance to Fire: Sand stones resist fire better. Argillaceous materials, although poor in strength, are fine in resisting fire.

Ease in Dressing: Cost of dressing contributes to rate of stone masonry to a great extent. Dressing is simple in stones having lesser strength. Therefore an engineer should look into enough strength rather than high strength whereas selecting stones for building works.

Seasoning: The stones obtained from quarry hold moisture in the pores. Strength of the stone improves if this moisture is removed before by using the stone. The procedure of removing moisture from pores is known as seasoning. The best way of seasoning is to permit it to the action of nature for 6 to12 months. It is very much needed in the case of laterite stones.