PROPELLER BALANCE

There are two types of balance of importance when working with propellers:

• Static Balance

• Dynamic Balance

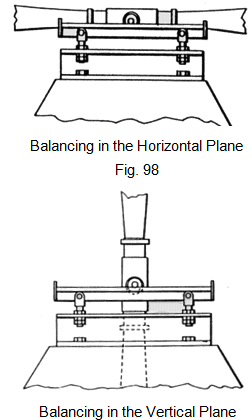

Static balance is checked and corrected at a propeller repair shop. The propeller is mounted on a mandrel and placed across perfectly level knife edges. The balance is check in two planes, one with the blades horizontal (Fig 98) and one with them vertical.

Fixed-pitch metal propellers are balanced in a propeller repair station by removing some of the metal from the heavy side and then refinishing the propeller.

Constant-speed propellers are balanced by placing a lead washer on a balancing stud inside the hollow blade shank. Small amounts of unbalance are corrected by packing lead wool in the hollow shanks on the bolts that fasten the halves of the propeller barrels together. This type of balancing can only be done by a certificated propeller repair station.

DYNAMIC BALANCE

Dynamic balance is the most effective type of balancing as it take all of the factors into consideration. It is done with the propeller installed on the engine in the airplane.

There are several aircraft balancers / analysers on the market that are essential for helicopter maintenance and extremely valuable for propeller balancing. The use of a microprocessor-controlled instrument that measures the amount of vibration and shows the position and amount of weight needed on the propeller spinner bulkhead to correct the out0of-balance condition is used through out the industry.

The equipment offers an option to split weights. If the location for mounting the permanent weights or the weight allowed per location is limited, enter the angles that are available and the unit will give a weight correction for each new location.

Install the permanent weights, and make a final engine run to ensure that they have the same balancing effect as the test weights.