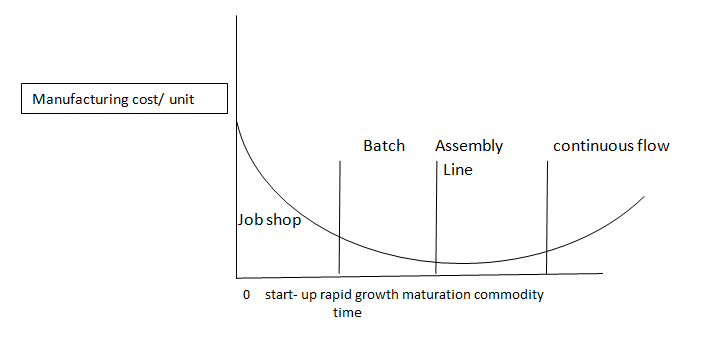

Process Technology Life Cycle

Process technologies have life cycles related to product life cycles as shown in figure below. Over time unit manufacturing costs diminish for mature products. Form product start up to decline, manufacturing processes change in organization throughput volume, rates of process innovation, and automation. To illustrate the process technology is typically job shop at start up and moves toward a continuous flow technology if the product survives to become a commodity. Throughput volumes and automation are low at start up and high during maturation and decline. These changes require appropriately matching up the manufacturing product and process structures.

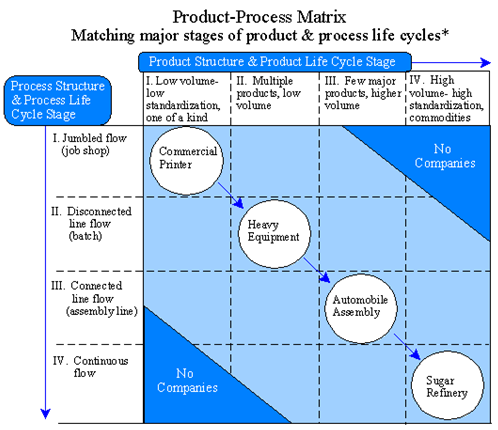

Typical combinations of product process structures are shown in figure below. Representative industries are listed on the diagonal of the matrix, and the voided corners indicate product process combinations that are incompatible and infeasible. Most companies divisions or plants can be located.

Figure: Matching Major Stages of Product and Process Life Cycle -The Product Process matrix.

On the matrix, depending upon the current life cycle stage of their dominant product line. As the product shifts to a different stage, the manufacturing process structure also shifts, and new manufacturing priorities emerge. Whereas manufacturing flexibility and quality are competitive priorities in earlier stages, priorities shifts toward dependable delivery and competitive cost in later stages.

This product process matrix helps us understand why and how companies change their production operations. As products, market requirements and competition change so must equipment procedures, and human resources. If process changes are not made to accommodate product life cycles product and process are incompatible: the result is competitive disadvantage.