Performance Criteria

This is assumed that an FMS is the part of a superior production process. Consequently the performance of the FMS is not a major goal but imply to attain cost-efficient timely production in the whole system. In hierarchical decentralized systems, the recent state of technology, complex production systems should be controlled. The decisions in the subsystems should be based upon local due dates and local earliest possible beginning times that are offered via the higher-level scheduling system. For a smooth operation of the whole system, a narrow distribution of the deviations from planned process is necessary.

Thus, the usual performance criterion is considered as minimal tardiness. Earliness is neither honored nor punished, since in a complex system the advantages of local earliness are doubtful. The tardiness of all jobs that are ended on time or earlier is zero. Throughput time or machine consumption are not utilized as criteria, since on the long run (we utilize extremely long horizons for the evaluation) the task of a production system is to generate the goods to be delivered on the right time where the demanded throughput times may vary extremely among the jobs; hence, the average throughput time might be a misleading indicator. Obviously, tardiness must all time be looks relative to a specific demanded flow factor distribution, indicated via the time pressure level in the present case.

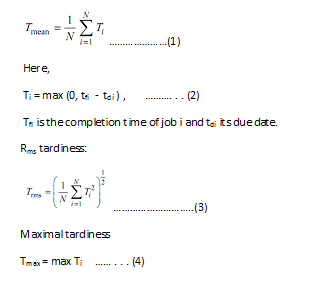

There are a number of various reasonable measures of tardiness. This is identified that these dissimilar measures in usual cannot be minimized concurrently. In cases of high loads of the system, algorithms which prefer shorter operations offer good values of average tardiness Tmean but at the expense of a minute fraction of the jobs that suffer from extremely large delays. If an FMS is integrated in a superior overall production process, not only a minute value of Tmean is desired but also a narrow distribution of the delays approximately this value, since larger discrepancies among planned and attained completion times create problems for the another local schedule. Thus, the subsequent three criteria are utilized:

Average overall tardiness (over all jobs)

Notice that Tmean is not subtracted in the definition of Trms, consequently Trms is not a variance but a measure of concerns tardiness and the dissimilarity of Tmean and Trms implies the width of the distribution. The associate emphasis is specified to any of the three criteria depends upon the exact situation. Generally, Trms will be the most suitable single criterion.