Oil Filter Debris Analysis

Oil filters serve an important function within the lubrication system of a gas turbine engine in that they remove foreign particles that collect in the oil system. Filters are removed at regular intervals for cleaning, any particles present can then be analysed visually. If visual inspection reveals evidence of excessive debris this can be more accurately analysed via ‘spectrometric analysis'.

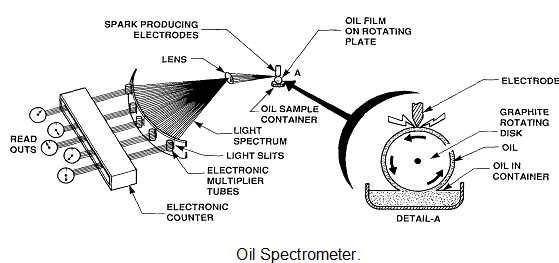

Spectrometric Oil Analysis Programme (SOAP)

Under certain conditions and within certain limitations, the internal condition of any mechanical system can be evaluated by the spectrometric analysis of the lubricating oil. The components of mechanical systems contain aluminium, iron, chromium, silver, copper, tin magnesium, lead and nickel as the predominant alloying elements. The moving contact between metallic components will, despite lubrication create wear, the debris resulting from this wear being carried away by the lubricating oil. If the rate of wear of each kind of metal can be measured and be established as normal or abnormal, the rate of wear of the contacting surfaces will also be established as normal or abnormal.

At specified intervals samples of oil are removed from the engine for analysis. Spectrometric analysis is possible because metallic ions emit characteristic light spectra when vaporised in an electric arc or spark. The spectrum produced by each metal is unique to that particular metal and, the intensity of the light can be used to measure the quantity of metal in the sample Again, information gained could be transferred onto a graph to show evidence of normal/abnormal trends.

In this process the oil is burnt which will also show on the analysis, but is ignored as a known substance. If we suspect that some or all of our fleet may have been contaminated by an incorrect oil, it is possible to sample the fleet using spectrometric analysis, to determine which components have the wrong oil in.