The maximum stress in each material:

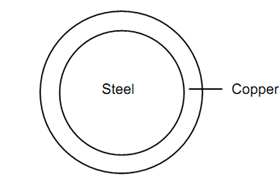

A copper tube of external diameter 60 mm and internal diameter 40 mm is closely fitted to a steel rod of 40 mm diameter to compose a composite shaft. If a torque of 6 kN-m is to be resisted by the shaft, discover the maximum stress in each material and the angle of twist in 2 m length.

Take G = 80 kN/mm for steel, and

G = 40 kN/mm2 for copper.

Solution

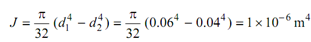

Copper Tube

G = 40 kN/mm2 = 0.4 × 1011 N/m2 , l = 2 m

d1 = 60 mm = 0.06 m

d2 = 40 mm = 0.04 m

TC = torque resisted by copper tube

θ= Tl/ GJ = (TC ) (2) /((0.4 × 1011 ) (1 × 10- 6 )) = 2 TC × 10- 5 radians ---------- (1)

τmax = (T/J )× R = (1 × 10- 6 ) × (0.03) = 0.03 TC × 10 N/m

= 0.03 TC N/mm2 ------------ (2)

Figure

G = 80 kN/mm2 = 0.8 × 1011 N/m2 , l = 2 m

d = 40 mm

J = (π/32) d 4 = (π /32)× 0.044 = 2.5 × 10- 7 m4

R = 20 mm = 0.02 m

θ= Tl / GJ = (TS ) (2) / ((0.8 × 1011 ) (2.5 × 10- 7 )) = TS × 10- 4 radians --------- (3)

τmax =(T/ J) × R = Ts / ((2.5 × 10- 7 ) (0.02)) = 0.008 TS × 107 N/m

= 0.08 TS N/mm2 --------- (4)

In composite shafts, θC = θS

⇒ 5 TC × 10- 5 = TS × 10- 4

∴ TC = 2TS -------- (5)

TS + TC = T

⇒ TS = 2TS = 6

∴ TS = 2 kN-m TC = 4 kN-m

∴ Angle of twist, θ= (2 × 103 ) × 10- 4 = 0.2 radians

Maximum Shear Stress

For copper shaft : For steel shaft :

τmax = 0.03 × 4 × 103 = 120 N/m2

τmax = 0.08 × 2 × 103 = 160 N/m2