Magnetic Detector Plug Debris Analysis of aircraft :

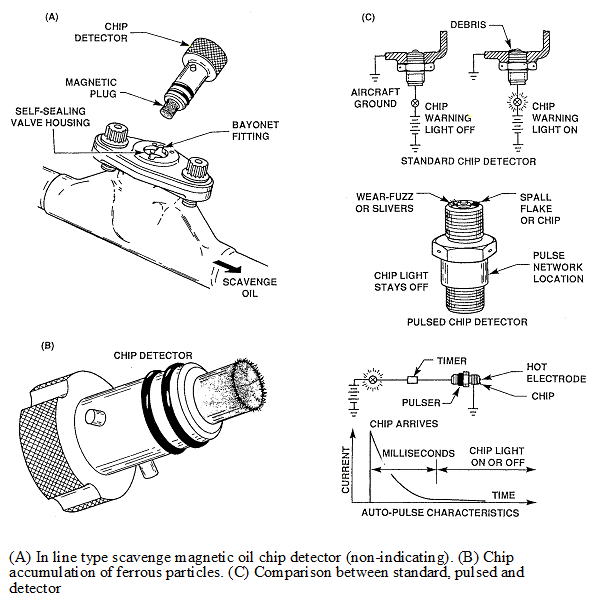

The magnetic chip detectors (MCDs), are small, permanent magnets installed in the scavenge/return lines of the engine oil system. They will attract ferrous debris from the oil. At specified intervals they are removed and visually inspected.

As a general rule, the presence of small, fuzzy particles or grey metallic paste is considered satisfactory and the result of normal wear.

Metallic chips or flakes however are an indication of a more serious nature requiring more in depth investigation.

Some organisations have specialised departments that, by examining debris under a microscope can, by virtue of shape, size, colour and marks determine quite accurately where the debris is from; ball bearing, roller bearing, gear teeth etc. They may also utilise a ‘Debris Tester' which will provide a means of measuring (magnetically) the mass of the debris produced. The figure gleaned can then be transferred to a graph which will indicate the normal /abnormal amounts of debris the engine is generating. A sudden increase in the amount of debris observed either visually or by graphs generated from debris tester figures may result in more frequent inspections of MCDs, or , in extreme cases, engine removal for subsequent strip examination.

An indicating type of chip detector may be used to give a warning in the flight deck if and when excessive debris is present. Basically the detector has two probes which if connected by the debris act as a switch to bring on a warning.

A much newer type of chip detector is the electric pulsed chip detector, which can discriminate between wear debris particles considered non-failure related, and large wear debris particles, which could be an indication of a more serious nature. Operating in a similar way to the indicating type chip detector, if the warning light illuminates, an electrical charge can be instigated either manually or automatically across the gap. Small wear debris particles will be ‘burnt' off and the light will extinguish. Large wear debris particles will however not burn off and the warning light will remain ‘on'.