Layout and operation of typical thrust reversing system:

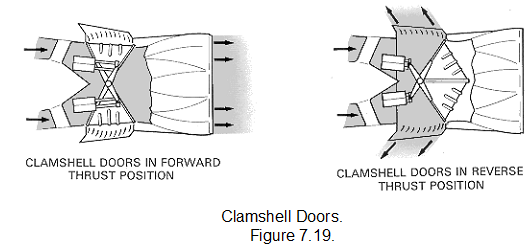

Clamshell door system

The clamshell door system is a pneumatically operated system, as shown in detail in fig Normal engine operation is not affected by the system, because the ducts through which the exhaust gases are deflected remain closed by the doors until reverse thrust is selected by the pilot.

On the selection of reverse thrust, the doors rotate to uncover the ducts and close the normal gas stream exit. Cascade vanes then direct the gas stream in a forward direction so that the jet thrust opposes the aircraft motion.

The clamshell doors are operated by pneumatic rams through levers that give the maximum load to the doors in the forward thrust position; this ensures effective sealing at the door edges, so preventing gas leakage. The door bearings and operating linkage operate without lubrication at temperatures of up to 600 deg.C.

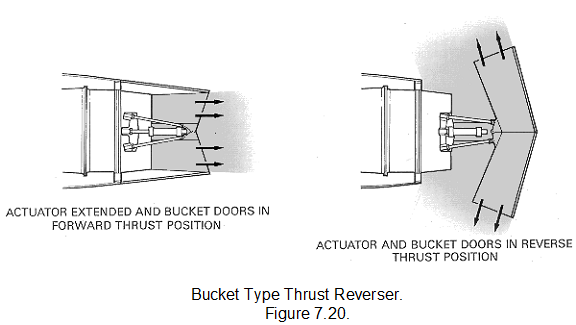

Bucket target system

The bucket target system is hydraulically actuated and uses bucket-type doors to reverse the hot gas stream. The thrust reverser doors are actuated by means of a conventional pushrod system. A single hydraulic powered actuator is connected to a drive idler, actuating the doors through a pair of pushrods (one for each door).

The reverser doors are kept in through the drive idler. The hydraulic actuator incorporates a mechanical lock in the stowed (actuator extended) position.

In the forward thrust mode (stowed) the thrust reverser doors form the convergent-divergent final nozzle for the engine.

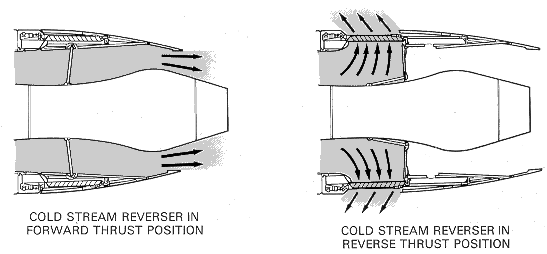

Cold stream reverser system

The cold stream reverser system can be actuated by an air motor, the output of which is converted to mechanical movement by a series of flexible drives, gearboxes and screwjacks, or by a system incorporating hydraulic rams.

When the engine is operating in forward thrust, the cold stream final nozzle is 'open' because the cascade vanes are internally covered by the blocker doors (flaps) and externally by the movable (translating) cowl; the latter item also serves to reduce drag.

On selection of reverse thrust, the actuation system moves the translating cowl rearwards and at the same time folds the blocker doors to blank off the cold stream final nozzle, thus diverting the airflow through the cascade vanes.