Question:

XYZ Textiles Ltd manufactures high quality value added knitted garments at its premises in the Industrial Zone in Plaine lauzun. XYZ has a daily capacity of 10 000 pieces daily and operates 6 days a week on a two shift system. XYZ is vertically integrated and is reputed in Europe for its high-quality products. Over the past six months, XYZ has lost major orders because of cost. The feedback from two major customers- one in Germany and one in U.K- has been that XYZ's prices are at least 15 per cent higher than those of its competitors with the same quality level.

A ‘Cost Reduction Team' (CRT) was set up, with representatives from sales, design, purchasing, finance, manufacturing and marketing. As Procurement Manager, you were an active member. In the past there has been no international sourcing, other than some spare parts and garments' accessories from the Far East. The raw materials are purchased from a local spinning plant and account for around 60 per cent of the cost of a finished garment.

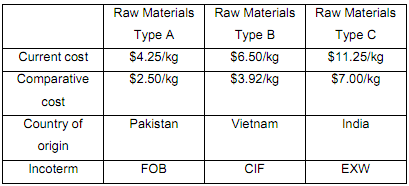

A friend of the Managing Director - Steven Gerrard, an import agent- was commissioned to look for sources of supply. He has now issued his report and presented the outline findings shown in the table.

It was agreed that you would consider sourcing the raw materials from overseas. The Managing Director has appointed you as Procurement Manager to conduct an exercise, to be completed within 8 weeks, with the objective of moving 50 percent of all raw materials purchases overseas by month 12 of the current year. He suggested that Procurement and Quality personnel visit the three countries and sources identified by Steven Gerrard as well as some other sources.

(a) Discuss the key issues that you will need to consider when sourcing internationally.

(b) How will you deal with major risks?