Forces in the members of the truss:

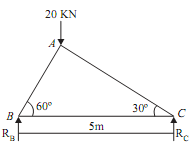

Find out the forces in the members AB, BC, AC of the truss shown in the figure drawn adjacent.

Sol.: First determine the reaction RB and RC. The line of action of load is 20KN which is acting at A is vertical. This load is at a distance of AB cos 60º, from point B. Now let us find out distance AB, The ?ABC is a right angle triangle having angle BAC = 90º. Thus AB will be equal to CB cos60º. AB = 5 X cos 60º = 2.5m Now distance of line of action of 20KN from B is = AB cos 60º = 1.25m

Now, taking moment about B, we get

RC X 5 - 20 X 1.25 = 0

RC = 5KN ...(i)

RB = 15KN ...(ii)

Let the forces in member AC, AB and BC is in tension.

Now consider the equilibrium of the various joints.

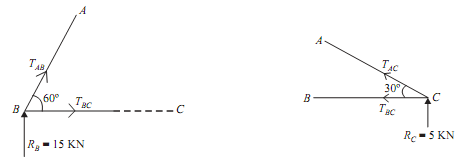

Joint B:

Consider free body diagram of joint B as shown in figure(a) Assume,

TAB = Force in member AB

TBC = Force in member BC

Direction of both the forces is taken away from B. As the three forces are acting at joint B. So

apply lami's theorem at point B.

TAB/sin270º = TBC/sin30º = RB/sin60º

TAB/sin270º = TBC/sin30º = 15/sin60º

By solving

|

TAB = -17.32KN

TAB = 17.32KN (Compressive)

|

.......ANS

|

...(iii)

|

|

TBC = 8.66KN

|

|

...(iv)

|

|

TBC = 8.66KN (Tensile)

|

.......ANS

|

|

Joint C Figure(b)

Consider free body diagram of joint C as shown in figure (b) Let,

TBC = Force in member BC

TAC = Force in member AC

The direction of both the forces is taken away from the joint C. As the three forces are acting at joint C. Thus apply lami's theorem at point C.

TBC/sin60º = TAC/sin270º = RC/sin30º

TBC/sin60º = TAC/sin270º = 5/sin30º

By solving

TAC = -10KN ...(v)

TAC = 10KN (Compressive) .......ANS

|

MEMBER

|

FORCE

|

TYPE

|

|

AB

|

17.32KN

|

COMPRESSIVE

|

|

AC

|

8.66KN

|

TENSILE

|

|

BC

|

10KN

|

COMPRESSIVE

|