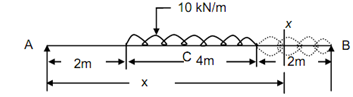

Find out the maximum deflection in beam:

A beam of span 8m is loaded with UDL of 10 kN/m over the middle half portion. Discover the maximum deflection. EI is constant.

Solution

By symmetry,

RA = RB

= (10 × 4 )/2

= 20 kN

Figure

M = 20 x -(10 ( x - 2)2) /2-(10 ( x - 6)2)/2

= 20 x - 5 ( x - 2)2 - 5 ( x - 6)2 ---------(1)

EI ( d 2 y/ dx2) = M= 20 x - 5 ( x - 2)2 - 5 ( x - 6)2 -------- (2)

EI dy/ dx = 20 x2 /2- 5 ( x - 2)3 /3-( 5/3) ( x - 6)3 + C1 . . . (3)

EIy = 10 x3 /3- (5/12) ( x - 2)4 - (5/12) ( x - 6)4 + C1 x + C 2 --------- (4)

at A, x = 0, y = 0, C2 = 0

at B, x = 8 m, y = 0

0 =10 × 83/3 - (5 /12 ) (8 - 2)4 - (5/12 ) (8 - 6)4 + C1 × 8

C1 = - 145

EI (dy/ dx) = 10 x2/3 - (5/3) ( x - 2)3 - (5 /3)( x - 6)3 - 145

EIy = 10 x 3 /3 - (5 /12) ( x - 2)4 - (5/12) ( x - 6)4 - 145 x

The maximum deflection at centre, since the beam is symmetrical and symmetrically loaded.

∴ EIymax =((10 × 43 )/3) - (5/12) (4 - 2)4 - (5/12) ( 4 - 6)4 - 145 × 4

ymax= - 1120/3EI