Exhaust gas temperature

Monitoring of the temperatures within the engine core is performed by the exhaust gas temperature system. The operating limits of the engine, and monitoring of the mechanical integrity of the turbines during operation, is vital for the continuing serviceability of the engine.

Exhaust gas temperature, abbreviated to EGT, is only one of the terms relating to gas temperature. It can also be known as:-

• turbine gas temperature (TGT)

• jet pipe temperature (JPT)

• turbine inlet temperature (TIT)

• turbine blade temperature (TBT)

• Intermediate turbine temperature (ITT)

The EGT system consists of a series of thermocouples arranged radially in the exhaust- section of the engine. The exact location is decided by the engine manufacturer; other components within the system are:-

• a thermocouple junction box

• a balance resistor box (junction box)

• indicators on the flight deck.

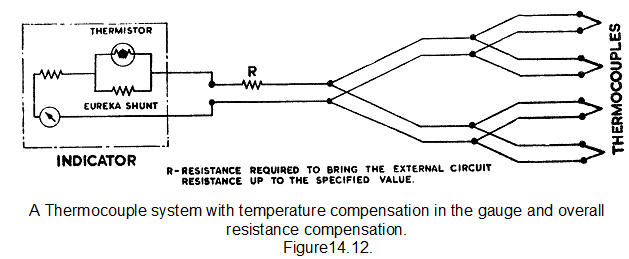

A typical system lay-out is illustrated in Fig. 14.12 .

THERMOCOUPLES

The thermocouple itself consists of two dissimilar metals joined together within the probe body. Gas inlet holes are provided in the outer casing to allow hot gases to circulate around the sensing elements. The most common types of dissimilar sensing wires used are chromel and alumel.

The probes may contain more than one thermocouple to sense the temperature at different lengths into the exhaust duct, or adjacent probes may be of different lengths. Some engines may have more than one EGT system. One for FADEC or for temperature limiting.

The junction of the two wires (within the probe) is known as the hot or measuring junction; the indicator end is known as the cold or reference junction.

The operation is fairly simple, as the thermocouple is a self-generating electrical system. Assuming that the reference end is kept at a constant temperature (flightdeck) and the hot end is subjected to high gas temperatures, then an electromotive force (emf), created by the dissimilar metals. The Seebeck effect causes the indicator to move in proportion to the difference in temperature between the two junctions.

The thermocouples are connected electrically in parallel to provide an average gas temperature. The two wires (chromel and alumel) from each thermocouple terminate at the junction box. The chromel wires are connected together to form a parallel circuit, the alumel wire is common to all thermocouples. The junction box can also be used to check the thermocouple continuity during maintenance checks.

From the junction box, the chromel and alumel wires are routed to the indicator on the flight deck.

In some installations the cold junction is not in the gauge, but is a separate thermocouple located in the intake. The benefit of this system is that when a top temperature system is used to trim the fuel control unit, the majority of the components in the temperature system are located on the engine. It will also indicate the temperature difference across the engine.