Evaluate the deflection at the free end of the cantilever:

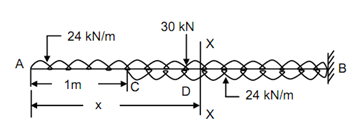

Discover the slope and deflection at the free end of the cantilever illustrated in Figure . Take EI = 200 × 106 N-m2.

Solution

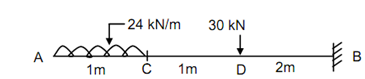

Apply Udl in both the upward and downward directions in the portion CB.

Figure

Figure

M = - 24 x . (x/2) + 24 ( x - 1) (( x - 1)/2) - 30 [ x - 2]

= - 12 x2 + 12 [ x - 1]2 - 30 [ x - 2] --------- (1)

EI (d 2 y /dx2 )= M = - 12 x 2 + 12 [ x - 1]2 - 30 [ x - 2] ----------- (2)

EI dy/ dx = - 4 x3 + 4 [ x - 1]3 - 15 [ x - 2] 2+ C1 --------- (3)

EIy =- x + [ x - 1] - 5 [ x - 2] + C1 x + C2 --------------- (4)

The boundary conditions are :

At B, x = 4 m, dy/ dx = 0 -------- (5)

At B, x = 4 m, y = 0 ----------- (6)

From Eqs. (3) and (5)

0 = - 4 × 4 3+ 4 (4 - 1) 3- 15 (4 - 2)3 + C1

∴ C1 = 208 ----------- (7)

From Eqs. (4), (6) and (7)

0 =- 4 4+ (4 - 1)4 - 5 (4 - 2) 3+ 208 × 4 + C2

∴ C2 = - 617 --------- (8)

∴ EI (dy / dx )=- 4 x3 + 4 [ x - 1]3 - 15 [ x - 2]2 + 208 ---------- (9)

EIy =- x4 + [ x - 1]4 - 5 [ x - 2]3 + 208 x - 617-------- (10)

At free end A, x = 0, From Eq. (9)

θ A = + 208 /EI = + 208 × 10/200 × 106 = + 1.04 × 10- 3 radians

From Eq. (10)

yA = 617/EI = - 617 × 103 × 103 / 200 × 106 = - 3.085 mm ( ↓ )