Estimate the manufacturing cost for a bearing housing following the Formula Student Costing Scheme.

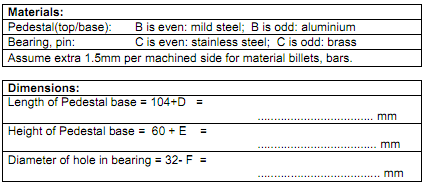

Dimensions and materials of the bearing housing will depend on your student number. Drawings and Solidworks part files are provided online, adjust the designs to your specific dimensions.

The Bearing housing assembly is composed by 4 components, plus fasteners:

1. Base of the pedestal

2. Top of the pedestal

3. Bearing (plain bearing for rapidly rotating shafts)

4. Locking Pin (interference fitting with bearing, loose fitting with pedestal)

a. Two threaded studs (fasteners)

b. Two nuts (fasteners)

If your Student number is ABCDEF:

Use Solidworks databases for the definition of material properties (such as material densities) and for the selection of suitable fasteners (Design library\ Solidworks toolbox)

The student is required to provide STAPLED TOGETHER:

1. The assignment sheet front-page (indicating your specific dimensions)

2. For each component and final assembly:

a. An individual costing worksheet with detailed description of the selected manufacturing process route (1 page per each costing sheet)

b. Associated updated engineering drawings with suitable tolerances and surface finish. Paper format: A4 BSI

3. Summary: Cost analysis for the bearing housing

a. Summary table detailing cost for parts and assembly

b. Table and Pie-charts detailing cost of materials and manufacturing processing (machining, set-up, assembly...).

4. Define the tolerance fitting required for the pin

5. Estimate the cost of making the threaded studs in comparison to buy the fasteners (assume alloy steel)