You have been requested by your Senior Engineer to design an Engine Control Unit (ECU) and prepare a report detailing your proposed solution. The client requires a design for a microcontroller based control unit for a new engine to be used in passenger vehicles.

You are required to design the hardware for an HC12 based Engine Control Unit, only as a circuit diagram. There is no actual hardware construction or testing required. This design includes external memory and bus circuitry, as well as the Input/Output hardware for interfacing with the engine itself.

You are required to complete this hardware design assessment by submitting your answers to the following questions in a short report format. Your report should include: a title page, numbering on each answer, your working for each question and either individual circuit diagrams for each question, or one large diagram with sections identified for each question.

Do NOT repeat the wording of the questions in your report. Your report is NOT to include copies of any data sheets.

Drawing of circuit diagrams using CAD IS NOT REQUIRED, but if you have experience with a suitable CAD package you may use it. Clear hand drawn diagrams are sufficient, but please draw using a ruler and use ink on the final design so it can be scanned and submitted electronically.

You must draw your own circuits. Do NOT use photocopies, scans or parts of circuits from any other circuit diagrams, with the exception that the pin outs for individual integrated circuits may be copied from data sheets or the study materials. You may use cut and paste methods to assemble components onto A4 or A3 size sheets and link them with clearly drawn circuit connections. (We suggest you draft in pencil, then do a final in ink)

For the HC12 microcontroller you may use a copy of the block diagram from page 29 or 30, from of the MC68HC912D60A.pdf technical manual provided on the course CD.

You may only select integrated circuit components from those provided in the course study materials, particularly:

1. An HC12 D60 microcontroller

2. The 74xxx series of logic devices. (see Appendix D)

3. The 27xx and 6xxx series of memory devices. (see Module 5)

4. The Motorola MCxxxx series of interface devices. RS232 buffers etc. (see Reading 4.4)

Any discrete components used, such as resistors, capacitors etc, should have their approximate values specified.

ASSIGNMENT REQUIREMENTS (Specification)

You are required to design and document the hardware design for a 68HC12D60 based Engine

Control Unit (ECU). This design includes the Input/Output hardware for interfacing with the engine, external memory and bus circuitry as described in questions below.

Assessment Questions

1. Block Diagram

Draw a block diagram of the ECU showing each element of the Engine Interface (see question 6) and Diagnostic Interface (see question 7), connected to an appropriate I/O port of the HC12. Clearly label the I/O ports used and the elements of the interfaces. (Eg. The tacho, fuel injector)

2. Microprocessor support

Draw a circuit diagram showing the minimum components needed to correctly operate the HC12 D60 microprocessor in normal expanded narrow mode. (That is - for external memory using an 8 bit data bus) You should ensure that:

(a) power is provided to the HC12 (assume a regulated 5V supply is available)

(b) interrupts are in their inactive condition

(c) the microprocessor E clock operates at 8MHz

(d) a reset circuit is provided.

(e) data and address buffers/latches are used as required.

You must specify part numbers and suggest values for any components used.

3. Memory Decoding

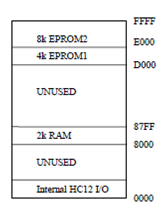

Figure. Required Memory Map

Draw a circuit diagram for the address decoding hardware required to decode external memory attached to the HC12D60 microcontroller, to match the memory map of Figure 1. You must show how the E clock signal from a HC12 is used in the circuit to enable the decoders at the correct time in the microprocessor cycle. Clearly identify all ICs used, label all pins on all parts and label the signals coming to and from the parts.

4. Memory Devices

Draw the circuit diagram for the connections to EPROM1 and the RAM device as defined in the memory map in question 3. You must show all the connections required to operate the memory devices. Clearly identify which ICs are used, label all pins on all parts and label the signals coming to the memory devices.

5. Timing Diagram

Draw a bus timing diagram showing the signals: E clock, address lines, data lines, latched address, the chip select for the RAM device and any other significant signals you have used in your circuit. Incorporate delays for decoders, latches and/or bus buffers that match your circuit design. DO NOT use copied or scanned diagrams from study materials. Draw your own timing diagrams.

Calculate the maximum read memory access time available for the RAM device drawn for question 4, using the timing delay values provided on page 420 of the MC68HC912D60A.pdf technical data manual and timing values for 74 series logic parts given in Appendix D. Assume an 8MHz E clock. Show your calculations.

Identify if the bus timing will function correctly or not. If it will not operate correctly, explain why it does not and how you would modify the design to ensure correct operation.

6. Engine Interface

Draw a circuit diagram showing how you would connect the Engine Control Unit to the engine components listed below. That is - show how these signals would be connected to the built-in I/O ports of the HC12. You should select appropriate ports and pins of the HC12 to match the signal types to best achieve the functionality required for that signal. (Do not use external I/O devices.)

Each engine component interfaced to the ECU circuit board requires an electrical connector to physically bring these signals to the PCB (Printed Circuit Board). Show each connector as a rectangle with numbered pins, clearly showing signal names and a GND reference. Label all pins on all parts and label the signals used in the circuit.

(a) The tachometer provides a 0 to 2.5 V analogue signal proportional to the speed of the engine. 0.0 V indicates 0 rpm, 2.5 V is equivalent to 8000rpm.

(b) The digital gear selection sensor is fully CMOS compatible and provides a 3 bit code indicating the selected gear as: 0 = neutral, 1 to 5 as forward gears, 6 is invalid and 7 as reverse.

(c) The accelerator position sensor provides a 0 to 5 V analogue output proportional to the position of the accelerator. The 5 V maximum signal level is provided when the accelerator is fully depressed.

(d) The Timing Trigger signal from the engine timing system produces a CMOS compatible active low pulse of 100μS duration.

(e) The Fuel Injector Pulse signal to the engine timing system requires a CMOS compatible active high pulse whose duration controls the length of the fuel injection period.

7. Diagnostic Interface

Draw a circuit diagram showing a serial port diagnostic interface for the Engine Control Unit incorporating the elements listed below. That is - show how these signals would be connected to the built-in I/O ports of the HC12. You should select appropriate ports and pins of the HC12 to match the signal types to best achieve the functionality required for that signal.

(a) The single indicator LED is required on the ECU to indicate the mode of the ECU. OFF for normal 'Operate' mode and ON for 'Diagnostic' mode.

(b) The single momentary push button (active low) input is required to toggle the mode of the ECU between 'Operate' mode and 'Diagnostic' mode.

(c) An RS232 compatible interface is required to provide a means to communicate with the ECU and to download new engine parameters in the form of a table of numbers. The amount of data downloaded at any time is approximately 2k bytes. This download task is to take no longer than a few seconds to complete. Show your calculations for the selection of a suitable BAUD rate.

Use a standard connector and driver/receiver circuitry for use with the RS232 interface.

Clearly identify which ICs are used, label all pins on all parts and label the signals used in the circuit.

7. Justification of Design

Write a brief justification for your choice of input/output connections to the HC12 that you used in questions 5 and 6. That is - briefly outline why you selected particular ports and/or pins of the HC12 to suit the operation of each interface. In particular you should consider how the ECU software might benefit from the use of interrupts on some connections.